A prototype otoscope incorporating Frauhofer’s technology, developed by US company OtoNexus Medical Technologies, is undergoing clinical trials.

Antibiotics are the usual remedy for infection of the middle ear, particularly among infants and young children. However, the equipment used to diagnose the condition has not developed for decades, and doctors can only deliver a diagnosis that is accurate in as low as 50% of cases, in particular in distinguishing between bacterial and viral infections. This means that many children are prescribed antibiotics unnecessarily.

Fraunhofer launches space radar and satellite technologies for avoiding orbital debris

Fraunhofer researchers develop system to find impurities clinging to components

The new otoscope, which is undergoing clinical studies, can tell doctors in a matter of seconds whether there is air or fluid in the middle ear, and characterise any fluid. This enables the doctor to distinguish between different stages of the illness and decide on the appropriate treatment.

“The classic otoscope is an optical system and hasn’t changed in decades,” explained Dr Sandro Koch, a physicist at Fraunhofer IPMS in Dresden. In the new device, the transducer emits ultrasonic pulses, captures the echo reflected from the eardrum, and generates a reading that tells the doctor about the degree of infection.

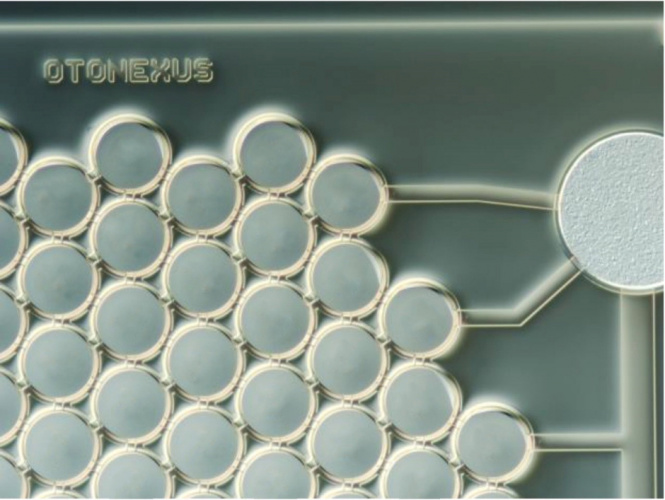

It features a capacitor formed by two electrodes separated by a small air-filled gap. One of the electrodes is flexible, and vibrates to transmit ultrasonic pulses. When the echo from the signal strikes a flexible membrane, the resultant vibration is converted into a detectable electrical signal. Software developed by OtoNexus analyses the echo signal. Initial clinical studies have corroborated the accuracy of the analysis, the institute said.

The transducer is a capacitive micromachined ultrasonic transducer (CMUT), produced on a silicon wafer by means of special microelectromechanical systems (MEMS) technology developed at Fraunhofer IPMS. The transducer has a low power consumption and can be mass-produced cheaply. Unlike traditional ceramic piezoelectric ultrasound transducers, it can be miniaturised, making it easier to incorporate in an otoscope.”

Market launch anticipated within a few years. Other applications could include smartphones and tablets for gesture control, or in vehicles to control on-board infotainment systems.

April 1886: the Brunkebergs tunnel

First ever example of a ground source heat pump?