Investment in the latest machine tool technology at Aylesbury-based CNF Precision Engineering called for a versatile workholding system, and the company turned to tooling specialist WNT.

According to CNF, the chosen technology, WNT’s MNG system, enables rapid and accurate changeover from one set-up to another, with multiple set-ups possible on a single base plate, and has ushered in significant time and productivity gains at the firm.

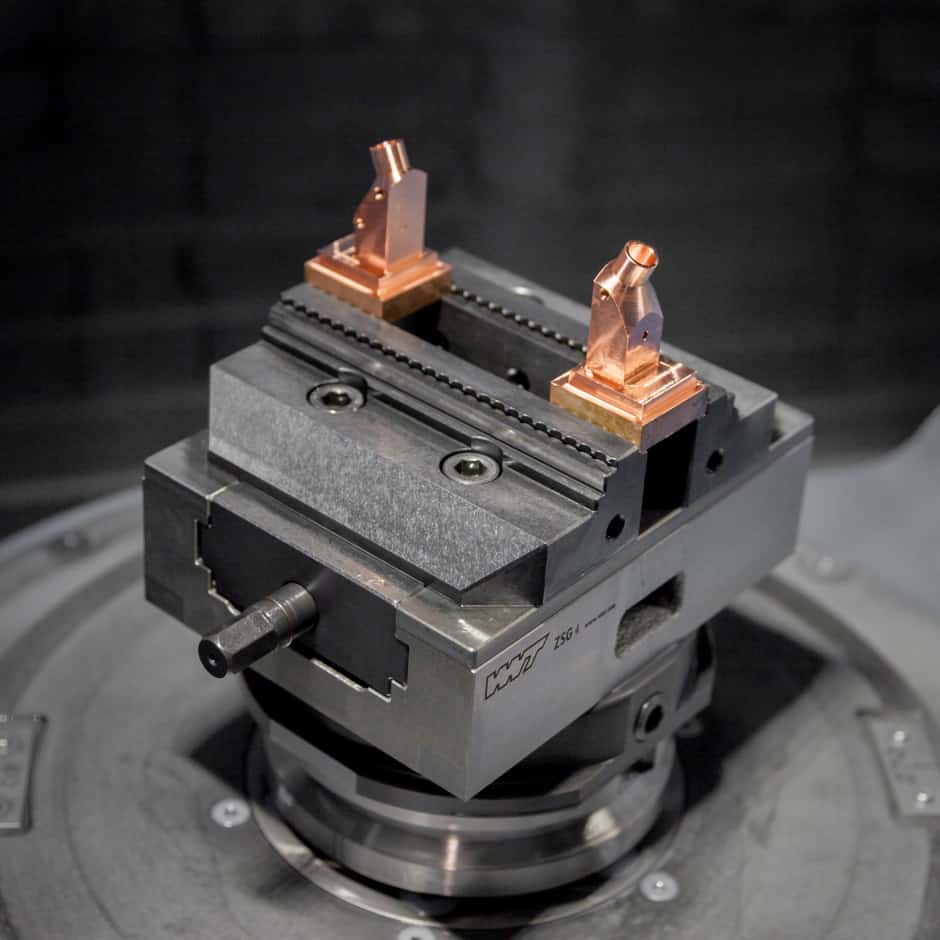

Initially every one of the 32 pallets on CNF Precision Engineering’s Matsuura MAM72-35V five-axis machine was equipped with single-position MNG Zero Point base plates. With the arrival of the Matsuura H-Plus 300-PC15 and MX-520 simultaneous five-axis machine, works manager Mark Baron looked to expand its use and introduced double- and triple-location MNG base plates.

“The WNT MNG system, along with the ZSG centric vices and ESG fixed-jaw vice, have proved to be highly versatile. We have added to them as we have progressed, making use of the different jaw systems available for the vices. While the majority of our set-ups are single parts per pallet, the ability to mix and match vices on the MNG base plates is an obvious advantage and allows for extended unmanned operation,” said Baron. “Another key feature is the enclosed leadscrews on the WNT vice system. We looked around and couldn’t find this feature on other vices. Given the number of pallets that we have, this feature is invaluable as we can’t afford the time to clean swarf from the leadscrews of all our vices, or indeed continually replace them due to swarf damage.”

The system has enabled CNF to maximise its multi-pallet machines, set-up is speedy due to the single clamping screw on the system and repeatability is guaranteed to within 0.01mm. A low profile of 30mm makes it suitable for five-axis machining.

The main vices in use at CNF are the ZSG 3 and 4 centric vice and the ESG 100 single-clamp systems. The ZSG range has a maximum gripping force up to 35kN and components up to 303mm in length can be held securely in its jaws, yet they remain very compact.

Red Bull makes hydrogen fuel cell play with AVL

Many a true word spoken in jest. "<i><b>Surely EVs are the best solution for motor sports</b></i>?" Naturally, two electric motors demonstrably...