But providing clean, safe water to remote communities in the developing world remains a challenge as there is often not the infrastructure in place to deliver it.

To reduce rates of diarrhoeal disease in remote communities, researchers at York University are developing monitoring technologies to allow local people to test the quality of their water supplies.

At any one time, approximately 1.8 billion people worldwide are accessing contaminated water, according to project leader Dr Steven Johnson.

“If we build a centre that the community could use, which would allow them to test the quality of their water, they could then decide whether to drink that water [as it is], access water from a different source, or to treat the water,” said Johnson.

The researchers are working with Oxfam and communities in Vanuatu, a collection of 80 islands in the South Pacific, which is known as the most disaster-prone country in the world. Following Tropical Cyclone Pam in March 2015, for example, half of the population went without clean drinking water for one month after two thirds of water and sanitation infrastructure was destroyed.

The technology will be co-developed with the local community, in a process the researchers have dubbed Integrated Participatory Technology Development, to ensure the resulting systems meet the needs, skills and environment of those living locally.

The co-development team will focus on two types of sensing technology, as part of the project, which is being funded by the EPSRC through the Global Challenges Research Fund.

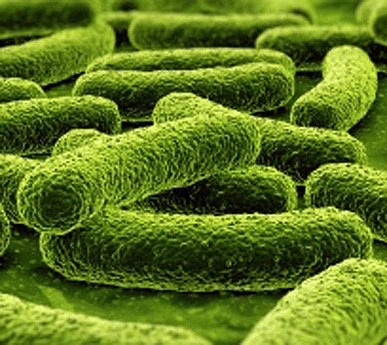

The presence of faecal coliform bacteria is typically detected by taking samples of water and growing any bacteria present on a plate, which can then be examined under a microscope.

“Rather than using an expensive microscope, we hope to use optical components similar to those inside a CD ROM drive, and combine it with some image processing, to automatically identify faecal coliform bacteria,” said Johnson.

The team will also investigate the use of nano-electronic and nano-photonic devices, integrated with probe molecules that bind to specific biological molecules within the water that are associated with the bacteria.

Collaboration to address viable solutions for VAWG database

Interesting to see what the funders say too..."The Innovation Launchpad Network+, .... brings together leading universities, the Catapult Network and...