The order builds on an announcement made on July 12, 2016 when Norsk Titanium revealed that Boeing had placed an order for titanium engineering test articles built using RPD.

In its latest announcement, Norsk Titanium said that Boeing designed the components and collaborated closely with it throughout the development process. To certify the initial structural components on the Dreamliner, Boeing and Norsk Titanium undertook a testing program with FAA certification deliverables, which was completed in February 2017.

“From the outset, the 787 has been the hallmark of innovation and efficiency,” said John Byrne, vice president, Airplane Materials and Structures, Supplier Management, Boeing Commercial Airplanes. “We are always looking at the latest technologies to drive cost reduction, performance and value to our customers and Norsk Titanium’s RPD capability fits the bill in a new and creative way.”

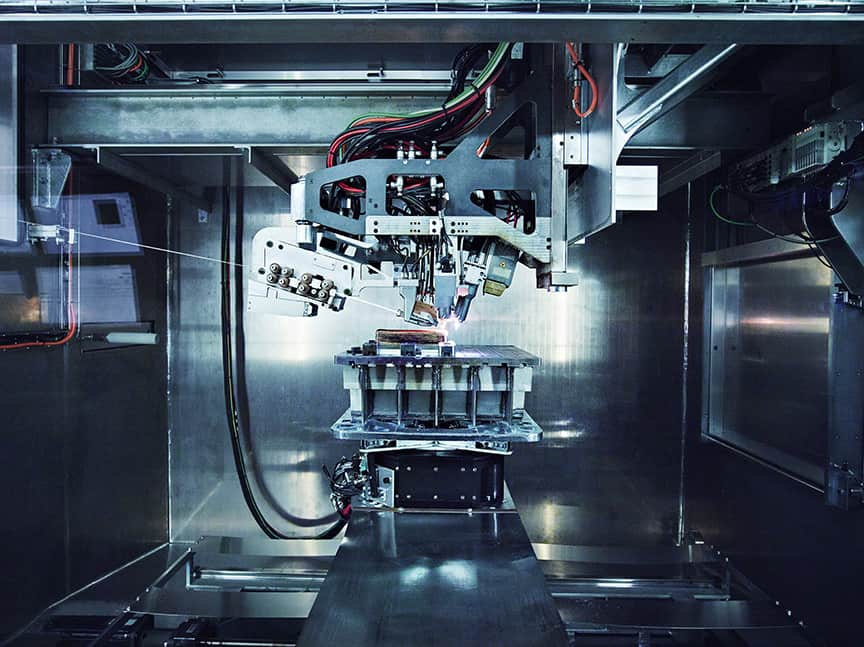

RPD works by feeding titanium wire into a set of plasma torches protected by a cool argon environment that has made it possible to replace legacy forged parts with additive manufactured components. Norsk Titanium RPD components are claimed to have equivalent strength to forgings, but are delivered inexpensively and efficiently.

Norsk added that it has signed contracts with aerospace manufacturers and tier-1 suppliers interested in utilising RPD to cut cost and lead time from airframe and engine programs.

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...