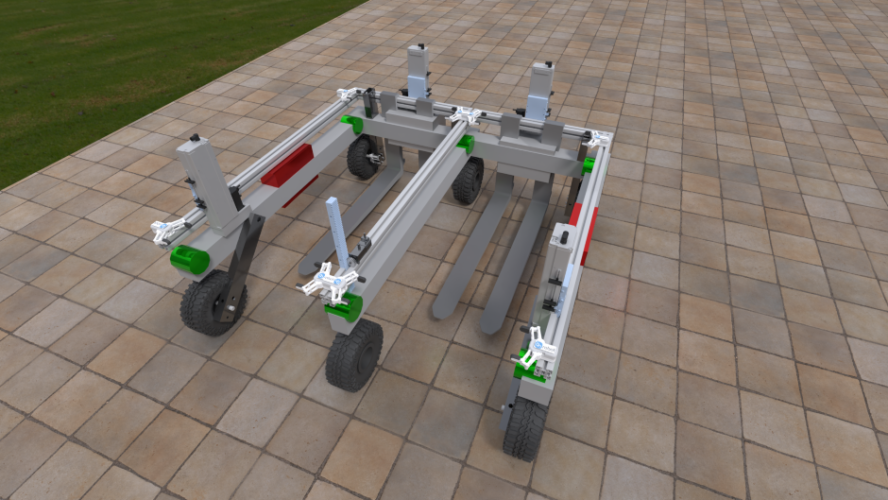

The AGV, created in conjunction with UK horticultural companies Crystal Heart Salad, Valefesco and WD Smith & Son, is being developed to work in greenhouse and outdoor areas moving trays and boxes.

Green machines: sowing the seeds of farming 4.0

Its development has been spurred by a drop off in available labour and the rising cost of the horticultural workforce.

According to Professor Robert Harrison from WMG, University of Warwick, the team reviewed existing AGVs to ensure there wasn’t an available product that could meet growers’ needs. They also ran a full analysis on the potential prototype to ensure the investment could be repaid through offsetting future labour costs. The overall goal is for the prototype to be developed commercially to cost around £30,000 to £50,000 depending on its configuration.

In use, AGVs navigate by following marked lines or wires on the floor, or use radio waves, vision cameras, magnets, or lasers.

“We are at a proof-of-concept stage evaluating a number of different options for guidance systems, and indeed for the mechanical design progression,” said Prof Harrison. “We do propose to use different guidance solutions in different situations, SLAM, GPS plus an indoor location system being the likely options.”

He added that the current configuration can carry up to around 20 crates, trays or boxes, depending on the variant of the design and size of the trays. The maximum load is likely to be between 100 and 200kg.

The AGV’s lithium battery needs to be recharged around every 1.5 hours, and the charging time is around 15 minutes (from 30 per cent to 80 per cent), Prof Harrison said via email.

The AGV is also being designed to be used in conjunction with application-specific attachments.

“We plan to integrate the AGV with various tooling to enable it to pick-and-place different forms of plant containers,” said Prof Harrison. “However, we are not currently focusing on planting or picking plants directly from the soil as a priority, as we believe we can add value more quickly and effectively in other areas of integrated-handling to begin with.”

The project is being funded by AHDB and match-funded by Innovate-UK-backed High Value Manufacturing Catapult.

Growers are invited to find out more about the project and to see how they can adopt automation into their businesses at a special event, hosted by WMG, on 31 March 2020. To book, visit ahdb.org.uk/events.

AI-generated medical responses need monitoring, study finds

This would negate most of the benefit of using AI in the first place, rather like the Locomotive Act 1865 that required any self-propelled road...