Catalytic process improves speed and efficiency of medicines manufacture

About 70 per cent of pharmaceuticals are manufactured using palladium-driven catalytic processes, which can be fast or efficient but not at the same time.

Now, researchers at North Carolina State University have now developed a so-called green chemistry method that reportedly combines aspects of both processes to improve efficiency at a minimal cost of processing time.

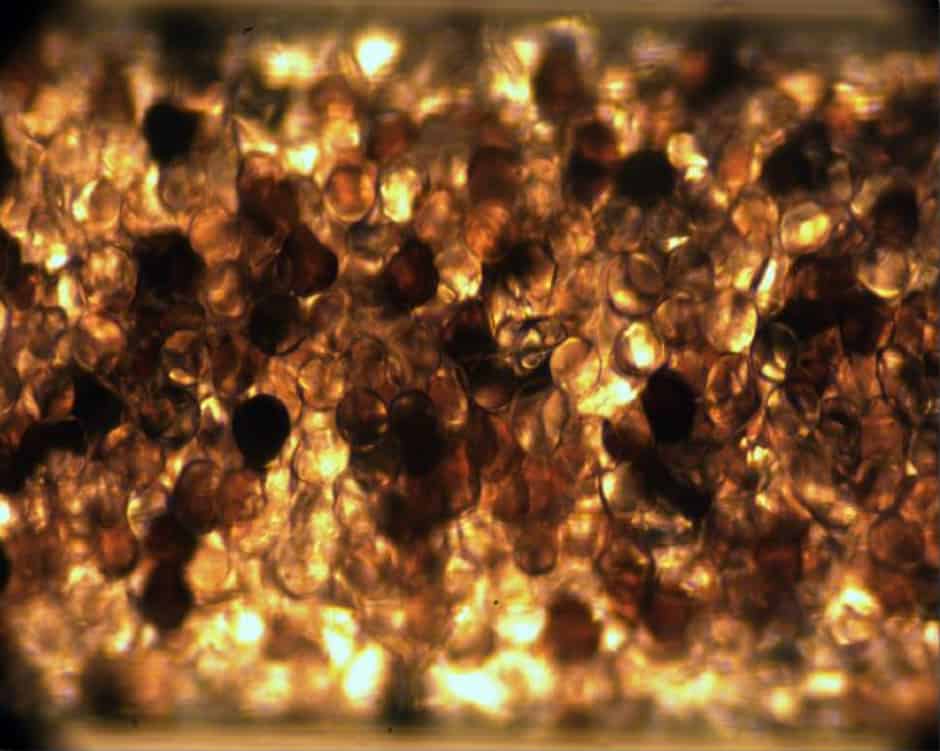

Palladium-driven catalytic reactions are used to connect carbons in small, organic molecules to create larger molecules for use in pharmaceuticals and other applications.

Until now, there have been two ways to do this, namely with homogeneous and heterogeneous processes.

In homogeneous processes, palladium is dissolved in solution, allowing maximum exposure to the organic molecules, or reagents. This makes the process very fast, but results in a lot of palladium either being wasted (because it gets thrown out after target molecules are harvested) or being recovered at high cost (because the recovery process is expensive).

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Simulations show Optimal Design for Bladeless Wind Turbines

"an 80cm mast" Really? I'm short but that's only half my height! Do they mean 800cm?