The company is using ‘lights-out’ manufacturing to run a precision engine part 24/7, supplying over 200 components per month to customers in Spain and the US.

Integrating robots into the process has removed the need for a second machine, freeing that up to cope with new contract wins that have seen turnover increase to £7.5m and the workforce grow 10 per cent to 70 staff.

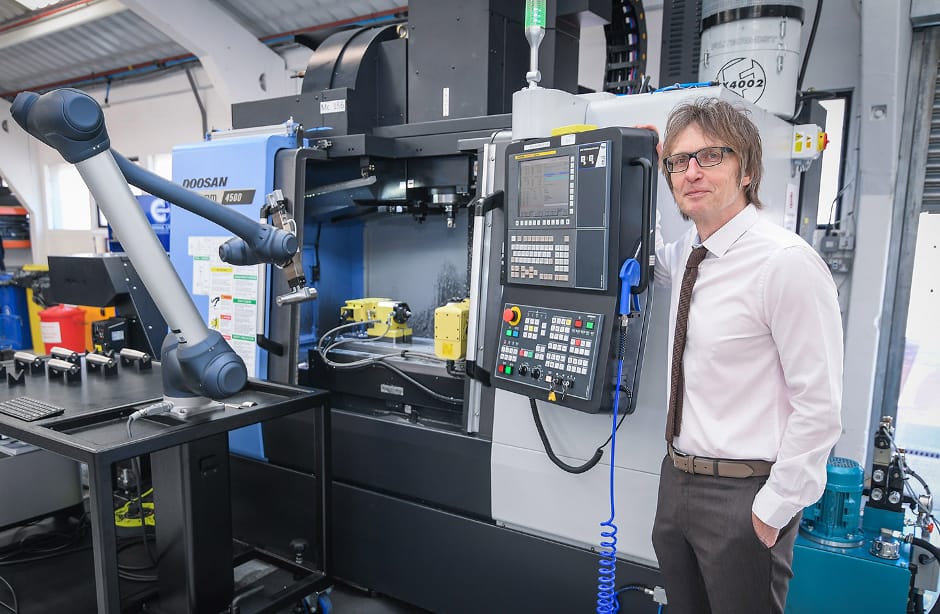

Jason Aldridge, managing director of Arrowsmith Engineering, said: “I’m a big fan of automation and don’t’ sign up to the notion that it’s taking jobs - if anything it will make us more competitive so we can take additional people on.

“The Doosan CNC machining centre and cobot system is our first investment in robotics and has been configured to suit our specific requirements for 24-hour manufacturing on a complex component for the aerospace sector.

“It has removed the need for an operator to load and unload the parts and this person has gone on to a different production process that is more skilled. This is just the start of what we hope will be a continuous investment drive in robots at our factory on Bayton Road.”

He continued: “It’s made us 15 per cent quicker and given us a 50 per cent capacity boost, that’s some payback already. Automation shouldn’t be seen as something that only the big boys do… SMEs can access it cost-effectively and we need to ‘grasp the nettle’ in order to bring the UK’s productivity up and in line with our international rivals.”

Based in Coventry, Arrowsmith Engineering is a specialist in precision turning, milling, thread rolling and grinding, providing components to aerospace tier 1s and primes in titanium, nimonics, stainless steel, exotic metal and engineering plastics.

The company, which has been supported by Coventry University and Coventry City Council on its latest investment, supplies parts that are used all over the world in aerospace engines, landing gears and air frame.

UK Enters ‘Golden Age of Nuclear’

Anybody know why it takes from 2025 to mid 2030's to build a factory-made SMR, by RR? Ten years... has there been no demonstrator either? Do RR...