Research into molten substances at the Diamond Light Source could have a big impact on additive manufacturing

The space-age silver disk of the Diamond Light Source sits in the Oxfordshire landscape like a recently landed flying saucer. Inside, powerful magnets accelerate electrons around a circuit shaped like a many-sided polygon and, at each shallow vertex, intense X-rays are directed into hutch-like laboratories where they are used to probe the properties of matter, helping uncover information about substances whose atoms form regular patterns. X-rays can penetrate crystals and the lattice structures of metals and their atoms scatter the radiation in characteristic ways that reveal how they are organised.

X-ray crystallography’s origins are in fundamental science. It has been instrumental in discoveries such as the structures of DNA and insulin, and it is widely used to help design drugs to attack viruses, bacteria and cancer.

It is also used by teams trying to find out what colour dinosaur feathers were and reading the contents of ancient documents, among other things. But Diamond is also a centre for industrial and engineering research, and a base for researchers looking at everything from the optimisation of automotive lubricants to probing the structures of engineering materials.

Prof Peter Lee’s research has a wider scope than most. Lee is professor of X-ray Imaging at the University of Manchester, but is based at Diamond’s Harwell campus, where he is assistant director of physical sciences. Lee’s research focuses on solidification and crystallisation of molten substances, which has taken his team into investigation of phenomena including the behaviour of magma inside active volcanoes, freezing of ice cream and, most relevant for engineering, how the processes involved in 3D printing (or additive manufacturing) influence the structure and properties of the materials formed in the process. This research has led Lee and his team to collaborate with Rolls-Royce on potential manufacturing processes for aerospace components, and the design of materials for surgical prosthetics that will bind to and encourage the growth of new bone through their structure.

Lee is involved with projects such as MAPP (Manufacture Using Advanced Powder Processes), the EPSRC’s £20m future manufacturing hub, which aims to usher forward the possibility of powders that are “active and designed, rather than passive elements in their processing”, where control of particles’ surface state and chemistry, internal structure, bulk chemistry, form, shape and size, will result in greater process efficiency and reliability, and product performance.

Another major project, AMAZE (Additive Manufacturing Aiming towards Zero waste and Efficient Production of High-tech Metal Products), ran from 2013 to June of this year with €18m European Union funding and involved 26 organisations, including Renishaw on the supply side; Volvo, Airbus, BAE Systems and the European Space Agency on the user side; and the Manufacturing Technology Centre, University of Birmingham, Imperial College London and the Fraunhofer institutes as research partners. “The difficulty with additive is that it works through trial and error,” Lee told reporters at a recent media event. “You can change the laser power, the powder density and so on but it’s trial and error how it comes out. We’ve made a machine that replicates the process in a way that we can X-ray. That’s allowed us to get all-new physics insights.”

Additive manufacturing aims to replicate the properties of wrought metal, Lee said. “Those properties include fine grain size with appropriate distribution of intermetallics, reinforcement phases, and often nano-precipitates that pin dislocations in the lattice, which improves strength. But, with additive processes, instead of having something that is very controlled as you are rolling it at a fixed temperature, you have a laser that heats at thousands of degrees a second, and you have molten pool afterwards that cools at thousands of degrees a second, and that produces completely different structures we really don’t know about.”

Understanding how additive forms structures in the metal and what effect this has on the properties could help refine the process by changing the conditions, Lee explained. “We find that the laser can disturb the powder. So, you can change the laser power but not just that, you can also use optics to change the distribution of the power by shaping the light. You can change the gas surrounding the printing, or the pressure of the gas, or the size of your particles and how they’re fed.”

With electron-beam printing, Lee has looked at ways of handling powder and operating the system so that the electron beam does not charge up the metal particles and cause them to repel each other electrostatically.

Lee’s current rig mimics the printing of a single layer of powder, so that the X-ray beam arriving into the hutch illuminates the point where the laser melts the powder.

But this rig will soon be succeeded by another, designed to mimic a Rolls-Royce process for repairing turbine blades. These are not the single-crystal cast blades that operate in the hottest part of a turbine engine, Lee said, but blades designed for operation in the cooler, less-demanding part of the engine. Using single-piece blisks rather than individually made blades welded onto a hub has reduced the cost of turbines but made repairs more difficult, he said. Rolls-Royce wants to be able to take blisks with broken blades, machine down the damaged part and rebuild the lost portion using metal powder blown concentrically around the point where a laser strikes the metal.

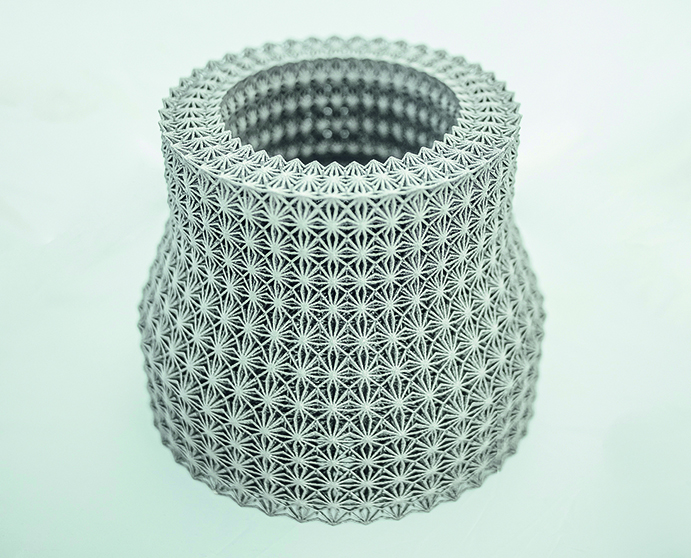

Lee’s group has also worked with the Joint European Torus nuclear fusion experiment at nearby Culham, trying to improve how highly neutron flux-resistant materials can be welded to or printed onto metals with efficient heat transfer properties. In the medical field, surface treatment to functionalise the parts of surgical prostheses that contact bone are under study. “Knee implants used to have huge spindles that went right onto the bone but these are now much shorter because of a printed surface lattice mesh into which bone can grow. We can see that because bone has different X-ray permittivity to metal,” he said.

Ice cream may seem trivial by comparison but is equally interesting technically, Lee said. “Taste depends a lot on structure; ice cream is made by shearing a mixture as it freezes to make small ice crystals. The crystals control how the taste molecules spread across the tongue; an ice cream with big crystals will taste sharper. Things such as fat inhibit ice growth, but so do other additives such as air bubbles, so we’re trying to find a way to make ice-cream where the crystals grow like it had fat in it, so it tastes the same but has half the calories.”

A worthy goal.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...