A £13m project is considering effective assembly procedures for ensuring appropriate quality and reliability for the electric vehicle battery packs of the future

If electric vehicles are to assume a central role in personal and public transport in the coming decades then several things need to happen to make that a practical reality not least the development of new more energy-intensive battery technologies and comprehensive recharging infrastructures.

But there will also have to be something else – effective assembly procedures using state-of-the-art techniques for ensuring appropriate quality and reliability for the battery packs that will provide the vehicles with their power source. Moreover they will also have to be procedures that can be scaled up with no compromise to those essential preconditions from initially low to much higher production rates as market demand increases.

Now, thanks to a two-year, £13m project that has just reached its conclusion, a prototype manufacturing facility that aims both to prove out the necessary procedures and to provide relevant companies with practical experience of them has come into existence in the traditional heartland of the UK’s automotive manufacturing industry.

The project, called AMPLiFII (Automated Module-to-Pack Pilot Production Line for Industrial Innovation), has involved a consortium of vehicle manufacturers, equipment suppliers and academic institutions with the first of those categories including Jaguar Land Rover, JCB and Alexander Dennis. The new facility itself is operated by project leader Warwick Manufacturing Group (WMG) at its base in the University of Warwick.

At first sight the compact facility looks modern but unexceptional, just a circuit of assembly stations – some open and manual, some enclosed and automated – linked by a conveyor system. But, as Prof Robert Harrison explained, the facility does not just embody current state-of-the-art manufacturing good practice it also exploits innovative product design to facilitate optimised production processes.

Indeed the “integration of product and process” is, he states, an absolutely fundamental element of the whole initiative.

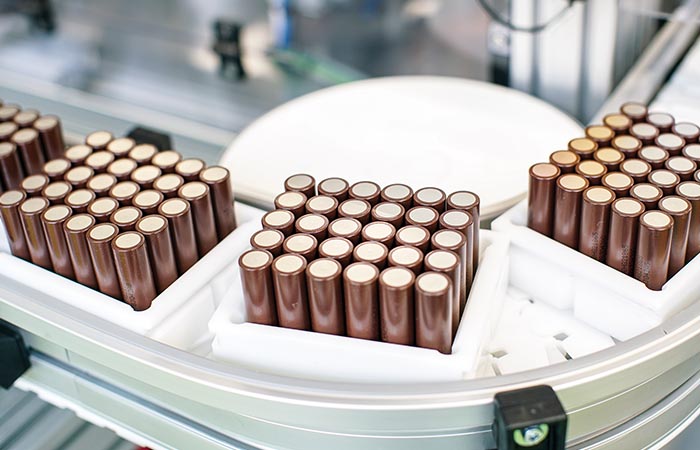

Right at the start, therefore, the project had to make a decision about the most fundamental element of the battery packs that would be developed for manufacture on the line – the size and shape of the individual lithium-ion cells that provide the basic power source. Prof Harrison said that the decision went in favour of cylindrical cells 18mm in diameter by 65mm in height simply because cells of that type are the most “widely commercially available”. As such counterparts with a square cross-section or even in flat ‘pouch’ form were discounted as candidates.

Product configuration

In the product configuration that the project has developed those basic units now form the starting point for a three-layer hierarchy. These are respectively: cell; module (a tightly packed collection of cells in its own framework with an integral busbar system to provide electrical connection between them); and pack (the number of interconnected modules that make up the complete power source for a vehicle arranged in a manner that suits the particular vehicle involved and with a single overarching ‘battery management’ system.

But, as Harrison further explained, the project has devised a form of physical packaging for the electrical components that supports comprehensive “flexibility and configurability” at each of those three levels.

The cells are held in a plastic framework comprising a latticework above and below to allow for busbar connections that is held together with solid sidewalls and end-strips. Those two elements can each be varied in size but are joined in different ways – adjacent sections of latticework being clipped together while ultrasonic welding is used elsewhere. The busbars themselves, by the way, which have pulsed arc welded connections to each end of each cell provide further structural integrity for the module assembly.

Harrison said that this format effectively allows for as few as just seven cells to form the most basic sub-division of a module and as many as a couple of hundred to be configured together to form a complete module. Moreover it also very cleverly allows groups of cells be placed either way up within that framework to allow for the creation of either serial or parallel configurations within a single module. In turn this ability to vary cell orientation supports the hugely important operational principle that complete packs can be either ‘high-power’ or ‘high-energy’, making them equally suitable for applications such as powering, say, respectively a piece of construction equipment moving very heavy loads short distances or a passenger vehicle transporting relatively light loads over extended ranges.

There are also, he added, other ways in which the configurability of the cell-module-pack sequence supports flexibility of use. One is in the choice of cooling technique between either the use of end-plates covering the top and bottom of each pack or flexible tubing carrying a water-glycol mixture running through the body of each module. Another is that the modules can be just as easily stacked on top of each other or placed side-by-side to exploit most effectively the physical space available within a vehicle.

The prototype manufacturing installation developed at Warwick to turn this product concept into a reality is, Harrison observed, a mix of current “good practice” and genuine “innovation”. Two sets of procedures on the line are, he says, “particularly critical”.

The first of these is the testing of each individual cell right at the start of the process, which is carried out fully automatically on batches of cells that have been loaded into a specially designed holder. “Every individual cell is tested for polarity, voltage and internal resistance,” he confirmed, after which it is accorded an individual identity that it retains throughout every successive operation. Cells usually carry an appropriate unique identification mark from their own manufacturer that can be utilised to support this capability. “The birth history of the system is recorded and from then on there is a no-faults-forward policy,” he observed, the point being to make “quality and traceability” fundamental elements of the whole set-up.

The second is the welding of the busbars to the cells. Again this is an automated procedure and once more product and process have been designed together. The novel physical feature in this case is the design of the tabs that are welded to each

end of an individual cell to make the required electrical connections. But as with the initial inspection the underlying principle of the manufacturing process is that of ensuring quality and traceability to which end, Prof Harrison confirmed, “each weld is logged.”

Very obviously, therefore, the supporting IT infrastructure for the installation is crucial to its effectiveness. Prof Harrison explained that infrastructure is not something that has been invented for the project but is instead an implementation of the Industry4.0 concept. The whole installation is, he said, “configured around a Profinet network with a gateway to Cloud analytics”. In turn, an important consequence of that is that the whole set-up can be easily reconfigured to meet new demands. “We can map new workstations into the system very easily,” he said, adding that this is aided by the fact that the whole set-up is highly modular with the control systems for each workstation co-located with them at the lineside and not installed ‘remotely’ elsewhere.

The first stage of the project formally concluded at the end of October and Harrison is confident that it has already got some real achievements to its credit.

Benchmarking of the product concept has shown it can achieve as much as a 30 per cent increase in the density of active material in complete battery packs over some systems on the market now.

Comment: The UK is closer to deindustrialisation than reindustrialisation

"..have been years in the making" and are embedded in the actors - thus making it difficult for UK industry to move on and develop and apply...