High resolution portable surface profiler uses confocal displacement sensors from Micro-Epsilon

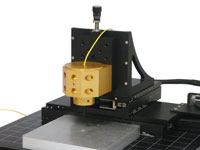

A new non-contact metrology system that provides portable surface profiling, imaging and thickness measurements down to nanometre resolutions, is utilising high precision optoNCDT 2401 confocal displacement sensors from Micro-Epsilon.

The Hornet3D is a new metrology system developed by Rhombus VS Ltd, a systems integration specialist based in Brackley, Northamptonshire. The company develops custom solutions for vision, non-contact metrology and automation applications, across a wide range of industries, including semiconductor manufacturing, photovoltaics, displays, electronics, medical, military, automotive, inkjet printing and thin-film solar panels.

Rhombus’ team of multi-disciplined engineers has extensive experience in high accuracy process and motion control, integrated software solutions, parts handling, robotic integration, beam profiling, laser processing, galvanometer scanning and calibration. Custom systems can take a variety of forms, from small standalone benchtop platforms to fully integrated 20-tonne systems for handling large glass substrates.

Hornet3D is the firm’s latest development and is a flexible, modular system that can be customised for specific surface profiling applications. The system can be specified with a range of different sensors and cameras, including Micro-Epsilon’s optoNCDT 2401 confocal displacement measurement sensor.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of premium content. Register for free to unlock unlimited access to all of our premium content, as well as the latest technology news, industry opinion and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...