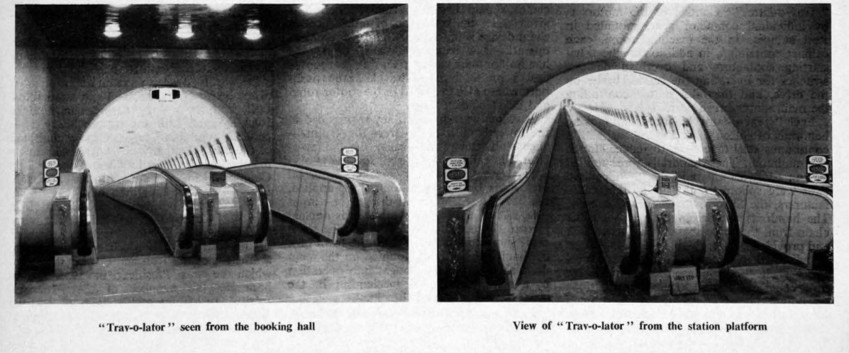

October 1960 - the dawn of the Travolator

In 1960 weary commuters let a moving walkway take the strain as they made their way through Bank underground station

Anyone familiar with London’s Bank underground station will know that it is a warren of tunnels connecting travellers to the DLR and three underground lines, or five if you count Monument station to which Bank is connected.

The station is a gateway to large parts of London but moving through it can be an arduous task due to its size.

In October 1960, The Engineer reported on a solution to moving vast quantities of people using the Waterloo and City line at Bank, a connection between Waterloo main line station and London’s commercial district with the Bank of England at its centre.

At 1 mile 1,012 yards, the Waterloo and City line is London’s shortest underground route. In 1960 it was carrying over 40,000 passengers a day, most of whom were travelling in the morning and evening rush hours.

“It was obvious even before the war that more trains were needed in the rush hours, but although augmented services were possible from a railway operating point of view, the then existing means of passenger movement to and from street level at the Bank station were inadequate,” said The Engineer.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of premium content. Register for free to unlock unlimited access to all of our premium content, as well as the latest technology news, industry opinion and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...