Selecting the Right Rolling Bearings

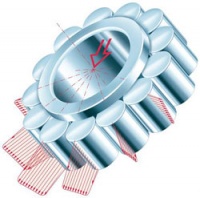

Rolling bearings are critical components in rotating machinery, production systems and vehicles. Here, Schaeffler provides some useful tips and guidance for engineers on how to select the most appropriate bearing for the application.

Mechanical design engineers often have to specify and select suitable rolling bearings. Even simple shaft systems subjected to radial and axial loads running at defined speeds can still place huge demands on the rolling bearings. The adjacent housing, for example, influences the shaft and the design of the bearings. Other factors such as temperature or sealing requirements are also important. The designer therefore has to find an appropriate method of supporting the shaft by using rolling bearings in such a way that the loads involved, the speeds required, the adjacent construction and environmental conditions, are all taken into account in order to ensure a reliably functioning shaft system.

In some cases, the designer may be able to use his or her experience and knowledge to design the shaft bearing arrangement. However, this could result in a bearing arrangement that is over-engineered and therefore not cost effective. Or worse still, the bearings may simply fail to fulfil the functions required of the shaft.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of premium content. Register for free to unlock unlimited access to all of our premium content, as well as the latest technology news, industry opinion and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

National Gas receives funding to develop Gravitricity underground hydrogen storage system

There can't possibly ever be a '<i>business</i>' case for the <i><b>bulk</b></i> storage of hydrogen, since Green hydrogen electrolysis...