Sep 1856: Ploughing ahead

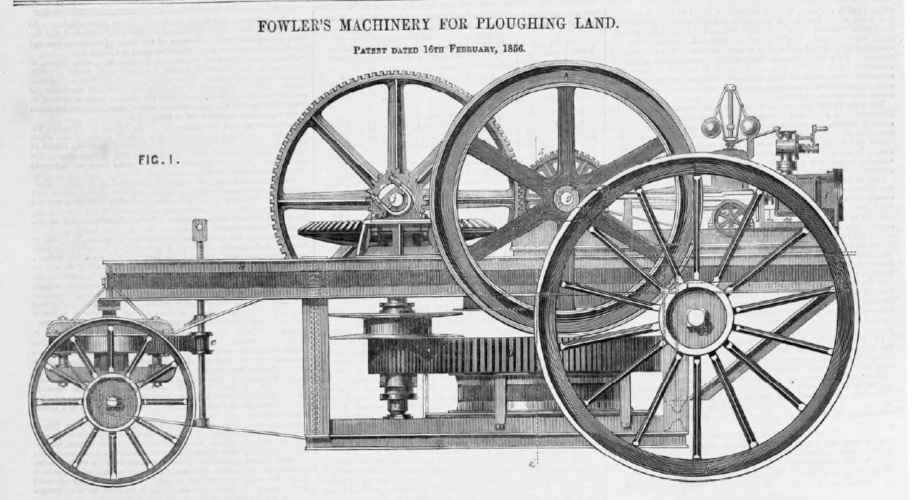

In September 1856, The Engineer reported on one of the latest developments in mechanised farming: Fowler's steam-driven plough. Jason Ford reports

John Fowler’s career as an agricultural engineer was inspired in part by a visit to Ireland in 1849 where he witnessed crop failure – and incredible human suffering - due to poor drainage.

On his return to England, he set about developing a horse powered drainage engine that would overcome the failings of the mole plough, a device used for drainage that is still in use today to lay small diameter pipes. In the nineteenth century, however, the mole plough was hamstrung by the need for considerable tractive power, which limited the size of the plough.

READ THE ORIGINAL STORY FROM THE ENGINEER'S ARCHIVE

His first two efforts saw horses turn a winch to pull the ploughs across a field with ropes, but by 1856 he had replaced horses with steam and came to realise that his ‘ploughing engines’ could replace horses to do the job of cultivation a well as cutting drainage channels.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of premium content. Register for free to unlock unlimited access to all of our premium content, as well as the latest technology news, industry opinion and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

National Gas receives funding to develop Gravitricity underground hydrogen storage system

One single rock salt mine - Winsford - has 23 <i>MILLION </i>cubic metres of void and even allowing for 10% of that void set aside for hazardous waste...