in automation and digitalisation are having a dramatic effect on the development and applications of bearing technologies. The Engineer spoke to experts from SKF, Schaeffler, and Igus to find out more.

Meet the experts

Phil Burge - PR and Brand Awareness Manager, SKF

Sally Sillis - Schaeffler Technology Centre Manager, Schaeffler UK

Matthew ALdridge - MD, Igus

What trends / customer requirements are driving developments in your product area?

PB: As many industrial companies introduce digitalisation to boost productivity and efficiency, raise product quality and make supply chain improvements, our service offering has shifted to embrace this.

PB: As many industrial companies introduce digitalisation to boost productivity and efficiency, raise product quality and make supply chain improvements, our service offering has shifted to embrace this.

Although SKF’s primary expertise is in bearings, the way in which we provide that expertise is changing. We continue to help customers improve their Rotating Equipment Performance (REP), but this is increasingly being achieved through digitalisation: adding sensors to machines, combining different data sources, analysing by combining the data with our application expertise and providing the right recommendations for corrective actions at an early stage and in real time.

While the technology itself is vital in gathering and crunching the data, it is the remote diagnostic service – where SKF experts interpret the data and make recommendations – that ensures optimal performance. Big data is the currency of modern industrial performance, but must be properly interpreted if it is to be of maximum use.

SS: Customers are increasingly looking to maximise availability, not only of equipment and machines but also of personnel. This means having real time, holistic knowledge of an entire production facility, not just key machines. Implementing smart devices can help free up maintenance staff to concentrate on more important planning tasks and to prioritise immediate and future maintenance requirements.

MA: Automation continues to be a growth area in manufacturing. This includes factories, production and assembly and now increasingly, the food production sector with vertical farming as well as traditional agriculture. With the use of intelligent technology, which igus calls isense, a monitoring system which accurately measures wear and reports back to master control, igus products offer predictive maintenance in areas with minimal direct human operation. This is driven by environmental considerations such as the requirement for the elimination of lubrication and the necessity of low energy production.

Give one or two examples of how your products are helping customers meet the challenges that they are facing?

PB: Digitalisation can be applied to any business and we’ve seen mining companies adopt it as readily as automotive companies, once they understand its benefits. In the mining industry, a customer installed 8,000 sensors on its production lines, monitoring 2,400 critical assets including pumps, fans, gearboxes and large rotating grinding mills. We have a continuous service agreement in place with the mine owners. As a result of digitalisation, SKF can show that these predictive maintenance measures are saving the company nearly £7 million per year.

SS: Schaeffler smart automatic lubricators for bearings ensure machine availability by delivering precise amounts of grease, reliably and when required to bearings in motors, pumps, fans and compressors – this frees up maintenance staff to concentrate on other tasks which require human intervention. It also helps to keep people safe, as they don’t need to access areas that are difficult or dangerous to reach.

SS: Schaeffler smart automatic lubricators for bearings ensure machine availability by delivering precise amounts of grease, reliably and when required to bearings in motors, pumps, fans and compressors – this frees up maintenance staff to concentrate on other tasks which require human intervention. It also helps to keep people safe, as they don’t need to access areas that are difficult or dangerous to reach.

MA: The isense system is a revolutionary product. Having a system that has the ability to predict any required maintenance before failure, is crucial in almost all industries. Having adaptable, off the shelf standard products that are lubrication-free, maintenance-free and intelligent are all helping to reduce bearing failures, maintenance and downtime. Having a low-cost intelligent range of products creates more efficient production whilst avoiding failures and allows companies to remain competitive by keeping costs down.

What’s the key product for you currently and how is it being applied?

PB: Industrial plants have hundreds and thousands of sensors continuously collecting assets’ data. Automated Machine Learning (AutoML) sifts through the massive amounts of data and chooses the optimal algorithms for analysing specific data streams. Our SKF Enlight AI system is an industrial analytics solution based on AutoML that has the potential to significantly improve machine failure identification. Thanks to our extensive and ever-growing library of algorithms, we are able to ensure the constant improvement of the AutoML performance, aiding O&M repair staff in establishing the root cause of machine failure more quickly and accelerating the remediation process.

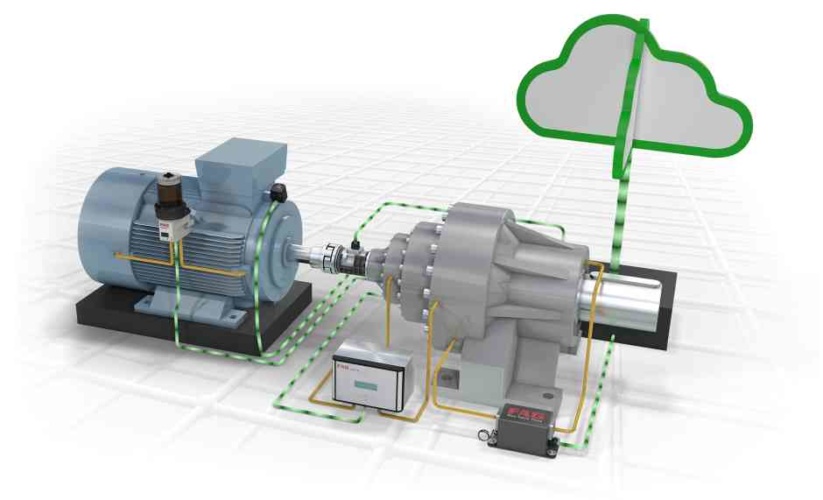

SS: ConditionAnalyzer is a digital service from Schaeffler for the monitoring of bearings in electric motors, pumps, fans, compressors and other rotating equipment. The service enables automatic analysis and simple, understandable communication of potential damage and severity across a complete plant. The output from ConditionAnalyzer can help avoid unplanned downtimes and maximise availability of assets. Personnel have the facts and can take the necessary action in line with production requirements and can plan for downtime if necessary. With ConditionAnalyzer, Schaeffler combines the expertise of its engineers in the design and manufacture of bearings with its many years of experience in interpreting vibration data and maintaining its own plants in one practical unique tool. Using this expertise, the ConditionAnalyzer uses vibration data from sensors that is automatically analysed and processed to reliably identify the bearing’s condition. The digital service does not provide the user with complex data, but rather a simple recommendation for action.

MA: It is difficult to pick out one key product in the igus range. The use of automated systems and the rise of intelligent products (smart plastics), are very interesting trends. For example, in the agricultural industry, igus linear gantries are used in automated planting, picking, weeding and sowing, whilst inside agricultural machinery, the iglidur Q2i intelligent bearing is used to provide wear rate feedback, which prevents machine downtime.

MA: It is difficult to pick out one key product in the igus range. The use of automated systems and the rise of intelligent products (smart plastics), are very interesting trends. For example, in the agricultural industry, igus linear gantries are used in automated planting, picking, weeding and sowing, whilst inside agricultural machinery, the iglidur Q2i intelligent bearing is used to provide wear rate feedback, which prevents machine downtime.

What products / technologies do you see changing your sector in the future?

PB: We are practising what we preach when it comes to digitalisation at our Gothenburg factory. As a result, we are the only industry manufacturer to assemble our spherical roller bearings using a process that is entirely machine-operated, automated and without human hands. This level of digitally interconnected high-level production, increases efficiency and production flexibility, and also completely changes the equation in terms of labour costs. As a result, we don’t need to send our production to a low-cost country to be competitive. World-class manufacturing, in this context, is simply a necessity for us, as SKF strives to keep a top position in the bearings market.

Also, thanks to condition monitoring and digitalisation, we are beginning to see traditional business models being replaced by performance and functional-based contracts. We have already begun setting up performance-based contracts with key customers that operate using a fixed monthly fee, with a bonus performance payment, added at longer intervals, if their KPIs have improved. This way of working has many advantages for both sides and we expect it to continue to increase in popularity, as more companies seek to exploite digitalisation to create different ways of financing operational performance.

MORE TECHNICAL PRODUCT Q&As FROM THE ENGINEER

SS: Digitalisation will continue to be a focus across all industrial sectors. Schaeffler’s components such as bearings and linear guidance systems are used in critical areas of machines, which produce critical information about conditions and movements. Schaeffler continues to invest heavily in research and development and has incorporated sensors, actuators and control units with embedded software into these products. With this, it is now possible for these parts to collect and process valuable real-time data on the condition of a machine and then convert this data into added-value services. Combined with Schaeffler’s system and modelling expertise, this real-time data forms the basis of a digital image of the machine that makes further analyses and digital services possible. These smart components become fundamental ‘enablers’ for Industry 4.0.

MA: The relationship where automated machines work alongside humans, enhancing and making factories a safer and more productive place has to be one of the most prominent and significant changes, and igus is seeing an increased demand for cable management in these robots. Also, remote technology is now a requirement rather than a luxury, for example, the igus D1 controller, which can be programmed from any device anywhere in the world.

Comment: The UK is closer to deindustrialisation than reindustrialisation

"..have been years in the making" and are embedded in the actors - thus making it difficult for UK industry to move on and develop and apply...