Efforts to beef up UK supply chains and encourage manufacturers to favour domestic production have been gathering momentum for a while now.

But the challenges presented by the Covid-19 pandemic – coupled with concerns over the impact of Brexit - have turbocharged these arguments and reshoring is now being seen as an increasingly important in terms of bolstering UK manufacturing resilience and ensuring that its manufacturing supply chains are fit for an uncertain future.

For this special report, in an effort to understand more about the benefits, challenges and practicalities of reshoring, The Engineer approached some of those at the sharp end of this phenomenon, including two firms who have actually recently reshored production to the UK: electric bike manufacturer Volt and Industrial hardware specialist Albert Jagger

But first, to get a broader perspective on the benefits of reshoring and the assistance that’s available we caught up with Make UK’s Senior Campaigns and Skills Policy Manager Bhavina Bharkada; and Julia Moore - Chief Executive of trade body, the GTMA and head of Reshoring UK, an initiative which is helping manufacturers tap into the UK existing supply chain.

How can reshoring benefit businesses and the wider manufacturing economy?

Julia Moore: Ever since manufacturers began outsourcing production to more competitively priced overseas economies such as China and India there has been a race to the bottom based on price. However, the overseas price advantage that enticed many businesses just a decade ago has been progressively eroded, but it is the combined business reality that the flexibility of local supply, quality issues, lead times, volume demands and easier face-to-face personal contact that is driving the need to return to UK suppliers.

Julia Moore: Ever since manufacturers began outsourcing production to more competitively priced overseas economies such as China and India there has been a race to the bottom based on price. However, the overseas price advantage that enticed many businesses just a decade ago has been progressively eroded, but it is the combined business reality that the flexibility of local supply, quality issues, lead times, volume demands and easier face-to-face personal contact that is driving the need to return to UK suppliers.

There is an intrinsic value attached to making things here in the UK, not least being the opportunities to innovate

There is an intrinsic value attached to making things here in the UK, not least being the opportunities to innovate. Reshoring UK highlights the skills and resources of the UK supply chains and aids manufacturers when considering domestic production for new projects or for the relocation ‘onshore’ of existing work programmes.

Of course, we do not expect that everything is going to come back to the UK, we are not so naive, but we are saying to those manufacturers, do consider dual sourcing. Something like this pandemic is likely to happen again. They need to consider how we mitigate our risk against being exposed to this situation in the future. With so much to be gained for both sides, manufacturers only need to look at the advantages of right-shoring, near- shoring whatever we call it to see the benefits of shortening the supply chains to gain the benefit of reducing costs, innovation and convenience of a supply chain to manufacturing in the UK, and we know that companies are taking steps in this direction.

Bhavina Bharkada: For manufacturers, reshoring is a form of diversification and this comes through our latest survey of manufacturers carried out over the summer. The results showed that manufacturers are diversifying their supply chains, with 15% using multiple suppliers, and a further 15% also reporting that they are increasing their use of local suppliers. Being able to draw on multiple suppliers, home or abroad, in different locations helps to reduce disruptions by spreading the risk. It can also increase agility as there are more supplier options to draw from.

Bhavina Bharkada: For manufacturers, reshoring is a form of diversification and this comes through our latest survey of manufacturers carried out over the summer. The results showed that manufacturers are diversifying their supply chains, with 15% using multiple suppliers, and a further 15% also reporting that they are increasing their use of local suppliers. Being able to draw on multiple suppliers, home or abroad, in different locations helps to reduce disruptions by spreading the risk. It can also increase agility as there are more supplier options to draw from.

It’s not a question of if another geopolitical event will occur, but when.

As we look ahead to the challenges manufacturers may face in the longer term, it’s not a question of if another geopolitical event will occur, but when. It’s clear that manufacturers will have to prioritise connectivity and diversification as ways of reducing risk. With increased investment in technology, UK manufacturers can do that by building smart, resilient supply chains that can withstand these external shocks.

Is reshoring actually happening in the UK?

Julia Moore: What Ventilator Challenge UK revealed was a whole world of subcontractors in the UK that OEMs have no direct knowledge of or contact with. This pandemic has exposed the frailties of many of the UK supply chains, highlighting just how reliant many have become on the overseas supply of critical items. There is now more impetus put on re-establishing UK production of these parts and protect SME manufacturing.

Even before the global threat from COVID-19 there was a paradigm shift from OEMs looking at the benefits of reshoring, as highlighted by the Lloyds Bank report ‘Business in Britain: Manufacturing’. A sponsor of the Reshoring UK facility, research from Lloyds Bank showed more than a third (37%) of firms asked said they were planning to move manufacturing processes back to the UK that had previously been offshored to territories like Asia and eastern Europe

The prime motive for this, cited by 71% of those with these plans, was to improve quality – a telling endorsement of the high standards that British manufacturers and workers uphold, which also has extremely positive implications for UK supply chains.

Some of the recent joiners of Reshoring UK have been prompted by current events and talk of onshoring activities. Now, there is greater power and resonance behind the core message of the initiative that is seeing momentum build and increasing its ability to engage with more organisations.

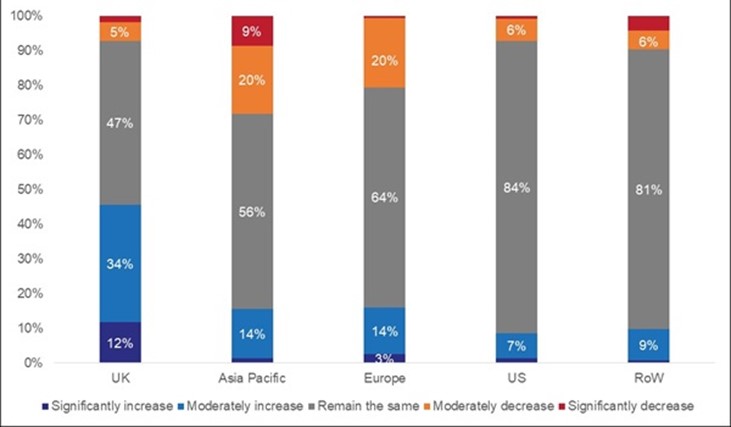

Bhavina Bharkada: Bringing manufacturing back to the UK is certainly a hot topic, but our survey also found that in spite of recent geopolitical events (including the pandemic) the proportion of manufacturers’ suppliers’ bases has not changed significantly in the past two years. Contrary to belief, there has not been a huge sway towards re-shoring, with only 21% of manufacturers saying they have moderately increased suppliers based in the UK. Global suppliers, whether in Europe or further afield remain important to UK manufacturing supply chains.

But as we look ahead to the next two years, our survey found over a third of manufacturers reported that they intend to moderately increase their use of UK-based suppliers in the next two years, with a further 12% indicating a significant increase. This is different to previous years which showed manufacturers had not significantly increased the number of UK suppliers.

Whilst this is only showing the intention to re-shore, it does indicate that manufacturers are beginning to address the international supply chain risks highlighted by Covid-19. Evidently manufacturers are looking to diversify their supply chains as a way of spreading risk, and exploring the options to use local suppliers is one option. Increasing their use of local suppliers was in the top three strategies manufacturers reported to have undertaken to improve their supply chain performance.

Instead, as we think about building supply chains that shift in focus from ‘just in time’ to ‘just in case’ we may see changes in where manufacturers’ supplier bases are. This includes diversification across different continents to help mitigate the impact of geopolitical events in one particular region. However it still remains too early to tell if attitudes have shifted and if supply chain networks will really shorten following the latest Covid-19 pandemic.

What are the key challenges involved in transferring manufacturing back from overseas?

Julia Moore: Everyone behind the Reshoring UK platform appreciates the complexities involved when transferring manufacturing from overseas. The website portal has been created to help re-establish the capability required to meet manufacturers demands and those businesses that have used it in this current crisis have realised just how much capability and competence is available within the UK.

The key thing is to get the primes, OEMs, and Tier 1s, involved in this. The pandemic threat has shown many businesses that they did not know where the tail-end of their supply chain was. It really has highlighted the frailty of the whole globalised manufacturing and logistical infrastructure.

Large manufacturers only need to look more closely at what is already available to them in this country

Manufacturers are constantly experiencing global shocks which affect their supplies. Companies transporting products across the world are constantly experiencing these blockages from political unrest, natural disasters, collapse of financial markets and perhaps for the UK with Brexit just around the corner our departure from the EU and the long term effects of this pandemic will affect our stability in the UK.

Reshoring UK’s aim is to bring the top and bottom of the supply chain together. With so much value to be gained by both sides, large manufacturers only need to look more closely at what is already available to them in this country, in terms of innovation, technology and quality and ease of access just how important this agile marketplace can be for cross industry knowledge transfer. Manufacturing is urged to seize this opportunity to reconsider its supply base.

Bhavina Bharkada: Transferring manufacturing back to the UK will be no easy feat. Long standing supply chain networks such as those in the automotive sector have been in place for many decades, therefore upping and moving them to any place will be challenging and costly. It can take many years to move supply chains, to setup new ones, and ensure that you have the people and skills to deliver this. With only 13% of manufacturers having full visibility of their supply chains, talk of reshoring may be premature. What the pandemic has done is highlighted that supply chains are critical for our sector and this needs to be an issue as important as people and finances. Tipping the balance further towards diversification through digitalisation will help manufacturers and the sector as a whole become more resilient, agile and responsive.

What is your organisation doing to help?

Julia Moore: Established over five years ago, the Reshoring UK initiative has been developing an online supplier database over that time. A key point about this facility is that it leverages existing trade associations, sector organisations and other groupings, some 26 currently. So, it is not recreating another network or group but building upon existing foundations that already exist. These existing organisations know their membership base intimately, and there is sustainability because they know whether each company is still in membership. They are responsible for maintaining that data ensuring reliability.

Reshoring UK is a neutral platform that clearly displays the depth of the UK SME supply chain universe. Any enquiries linked to suppliers are distributed to the supplier’s trade association; the link is always between the association and its member. A strength of a trade association is that it can create a supply chain or cluster group for an industry need from within its membership.

For example, through our Medical Cluster of 100 companies, the GTMA was involved in early March 2020, working with UCL on the CPAP ventilator in which our members were involved, proving SMEs are agile and can transfer their skills from automotive to medical manufacture.

Bhavina Bharkada: Make UK are supporting manufacturers to build smart, resilient supply chains by adopting and embracing digital solutions. Whether it’s web-based or cloud-based solutions, better visibility through digitalisation will prove advantageous in the medium to long term. Our series of blogs with practical steps on what manufacturers need to be thinking about when it comes to supply chains is available on the Make UK website. You can also access our free webinars in partnership with Oracle where we discuss practical steps with manufacturers too.

Reshoring Case study: Moves like Jagger

Mark Hilton and Andrew Cooper, Operations Director and Director at industrial hardware specialist Albert Jagger explain how reshoring put the company in total control of its product.

Having initially conducted a risk assessment of our supply chain and evaluated the financials around the entire reshoring process, we realised that once we factored in all of the shipping, the handling of port and the environmental impact, the overall terms were far better for the customer and the outgoing cost was cheaper for Albert Jagger. Following this, we then took it upon ourselves to ‘myth bust’ many of the misguided perceptions attached to procuring from China – especially with regards to the total procurement cost.

We then invested £300,000 in the necessary equipment to manufacture that product in the UK as well as reskilling our workforce to operate our new CNC machines – the Citizen Cincom L20 and L32 machine and the IMECA Boss 338 HD bar feeders.

By reshoring our manufacturing operations back to the UK, we are now in total control of the product from start to finish.

Key benefits

Originally we were forecasting to make 750,000 units per year but after securing multiple contracts since finalizing the reshoring process we are now expecting that to increase significantly to 1,500,000 per year.

This substantial rise in sales was generated as a result of the fact that we are now able to demonstrate absolute control over the supply chain. By bringing our manufacturing operations back to home soil this has also shortened the chain – which has benefited our customers significantly as they no longer have to commit themselves to purchasing thousands upon thousands of unit inventory. Meaning that rather than focus on the cost per unit, customers are now looking at the benefits of having units available to them at their preference. This also has allowed us to avoid a price war.

Key challenges

The closure of the factory for a month in order for it to be improved upon was probably the most hard-hitting obstacle. As, the core challenge was working with our head office for weeks and months to ensure that whilst our factory was closed parts were still available to sell.

To ensure that the manufacturing output was maximized, we had to make improvements to the factory’s layout, roof, flooring, quality department and lighting. In essence, for the process to be done correctly we were forced to invest in an entirely new factory. In total these improvements totaled around £500,000.

We also had to commit to £320,000 of capital investment into two CNC Machining Centres and to improving the tooling in the press shop.

Another core piece of investment was in the staff as they had to be trained in a brand-new skillset – predominantly in CNC proficiency operation and programming.

Helping hand

We worked very closely with the MTC, whose assistance was vital in ensuring the reshoring process was possible. They facilitated the optimisation of the layout of the factory by using state-of-the-art virtual reality software and hardware and ensured our workforce had a complete understanding of the entire process as it was not as simple as just reshoring the product. Whilst we didn’t necessarily lack the skills to change, the MTC highlighted certain issues and brought them to light, which was simply not possible to do without their help.

By being able to see where the new workstations would be positioned and how they looked through virtual reality, the MTC helped build the relationship of trust between our staff and the management team. They also worked with us to make more efficient layouts, assisted with costing, helped come up with progression tooling and most importantly set deadlines for everything.

Key advice

Probably two core pieces of advice would certainly be to start with the data and to get a handle on the total cost of importing your products – whether it be from China or an alternative market, and to not be afraid of challenging the status quo.

Once all the costs are factored, businesses will be able challenge and ‘myth bust’ many of the preconceptions regarding procuring from overseas. One such being that for Albert Jagger in particular, it was no longer cheaper to purchase from China.

Planning, as well as taking stock of what infrastructure, equipment and skill set a business has at its disposal is also vital. For these reasons, we also recommend to sticking to reshoring a family of products rather than use the scattergun approach of bringing back a catalogue of different items.

Reshoring Case study: Volt - from Poland to Milton Keynes

James Metcalfe, Co-Founder of UK electric bike manufacturer VOLT explains why and how the company relocated manufacturing from Poland to the UK

James Metcalfe, Co-Founder of UK electric bike manufacturer VOLT explains why and how the company relocated manufacturing from Poland to the UK

After ten years designing and building e-bikes, we had outgrown our Polish surroundings, and the need for a bigger, bespoke factory arose.

It has been a long-term aspiration to onshore and centralise the firms’ manufacturing process to the UK. With an exit from the EU looming, we couldn’t risk any customs hold-ups or disruptions so the idea of a new factory in Milton Keynes quickly took shape.

Fast-forward to June, we have opened the doors to our new facility in Buckinghamshire that has the capacity to build up to 25,000 e-bikes per year and create 30 new jobs in the local area.

The new manufacturing base positions us for accelerated growth and reinforces our commitment to British manufacturing and high-quality production.

The benefits of reshoring

Milton Keynes is an enterprise hotspot and an innovation hub with exceptional UK-wide distribution links. The surrounding area provides a source of exceptional talent, and since some of the largest bicycle component distributors are also based in the area the sourcing of parts is quick and convenient. For example, having Japanese giant, Shimano close by is fantastic because we build our bikes using a lot of Shimano parts.

The move has also enabled us to have localised control of production, so we can operate more fluidly across the manufacturing cycle. This gives us the ability to massively improve production efficiencies and to quickly drill down into and iron out any issues that arise. We can make refinements quickly and have greater hands-on control.

Key challenges

Of course, it was a large financial investment but one that we knew was necessary to take VOLT to the next level. Across the past year, there has been an increasing interest in e-bikes and we’ve seen a surge in the number of people turning to e-bikes as a transport alternative so we needed to grow quickly to match this demand.

There were also psychological barriers for us to get over – it’s quite a challenge and when you historically have seen manufacturing leave the country, encouraging it to come back in seems a bit counterintuitive: you question if you’re doing the wrong thing. We really had to weigh up the pros and cons of moving production to the UK to be sure we were making the right move.

Assistance and help

As a family business, we are generally dependent on our own skills to manage the entire operational process of our expansion, and have historically not relied on outsider support at all. Ultimately for this move we have again used our knowledge of manufacturing, albeit from outside the UK, and brought this knowledge and the processes we had already ‘tried and tested’ into this new UK plant. Alongside this we have welcomed the advice of friends within industry to give us guidance on best practice routines for designing perfect flow and layout protocols.

Key advice

Even if it costs you a bit more to manufacture in the UK, what you gain from doing it in the control aspect and the timings definitely has a lot of value associated to it.

If considering reshoring I’d advise to make sure you have a planned contingency stock holding which gives you the breathing space to make a few mistakes whilst you learn and implement all your new processes.

And importantly, invest time into putting the best systems you can in place for managing every aspect of your Bill of Materials, which in turn will help you avoid expensive production and operational delays, and will save you money.

Plasma technique converts landfill methane to jet fuel

Trevor; there are still many landfill sites in the UK where the methane is not captured but not only that, where there is protein waste in them, they...