Rigours of wind prompt Ricardo bearing rethink

The rigours of turbine operation have prompted a rethink on bearing design. Dave Wilson reports

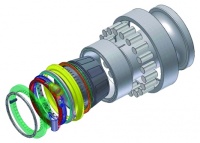

High in the air and buffeted by gusts and gales, wind-turbine gearboxes present a range of opportunities for failure. The durability of these bearings is therefore key – especially on offshore wind farms, where cost of maintenance is high.

Engineers at Ricardo, who have developed cost models for gearbox-maintenance activities, estimate the typical cost of a repair arising from the failure of certain bearings at €430,000 (£370,000) for an installation 20km offshore. This is based on a North Sea installation with average weather patterns for a fault arising in October. The high cost and long downtime threatens the viability of commercial offshore installations, but also provides the opportunity for engineers to add value to a component that may cost less than €1,000 (£870).

Ricardo has designed a solution that it believes could make the service life of bearings in such gearboxes six times longer. Funding from a share of £3m, provided by the Northern Wind Innovation Programme (NWIP), will see the company work with a manufacturer of large industrial bearings and academics at Sheffield University to take the concept further.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of premium content. Register for free to unlock unlimited access to all of our premium content, as well as the latest technology news, industry opinion and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...