As the boundaries between once distinct sectors become ever more blurred and new technologies transform the way that engineers work, UK industry’s skills demands are changing fast.

Add to this the fact that the sector is increasingly competing with other areas of the economy for expertise in emerging areas - such as data analytics and AI - and it’s clear that when it comes to tapping into the best available talent, engineering employers face some considerable challenges.

Unsurprisingly, these challenges are also a key priority for the various organisations committed to helping industry get the skills it needs, one of which is newly launched employer-led body Enginuity – formerly known as Semta – which is on a mission to revitalise the way that industry nurtures and attracts expertise.

The Engineer caught up with Enginuity CEO Ann Watson ahead of its relaunch to discuss the nature of industry’s skills challenge and find out how the new organisation plans to address this head on.

The need for data and digital skills is increasing and we’re seeing a huge upskilling challenge

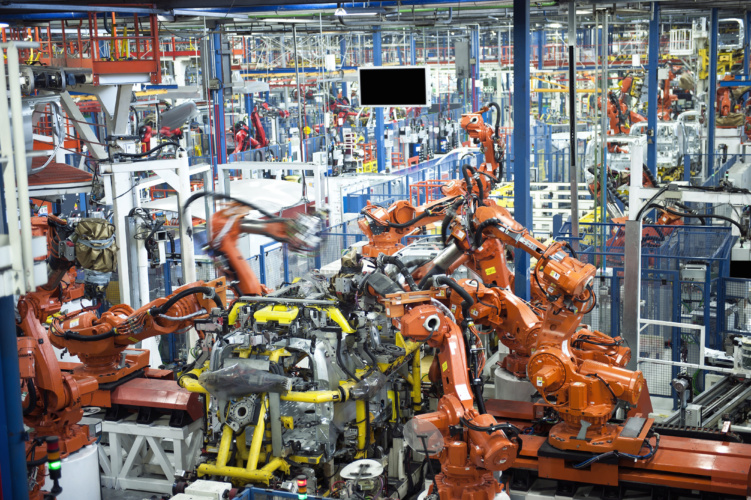

CEO since 2015, Watson has had a front-row seat on industry’s changing skills requirements in recent years. “It’s a really challenging time for employers,” she said. “Skills have been top of the priority list for a number of years, and as we move into the world of Industry 4.0 those skills challenges are changing. The need for data and digital skills is increasing and we’re seeing a huge upskilling challenge. Sixty per cent of the manufacturing workforce of 2030 have already left school, and these are the individuals that we’ve got to upskill.”

The difficulty employers face addressing all of this is, she added, compounded by the speed of the change. “Employers are telling us that whilst in the past job roles might have changed every 10 years, they’re now changing every 3 years, and this requires constant upskilling and reskilling of the existing workforce.”

Against, this backdrop, it’s also becoming increasingly difficult for employers to second-guess what skills they’re likely to need in the future, said Watson. “What they’re telling us is that in five years’ time we don’t know what an engineer’s going to look like but what we need is someone that’s got a broad range of skills that can be applied to different situations and technologies.”

The launch of Enginuity is, she said, a direct response to this situation, and borne of a realisation that to be fully effective the skills sector itself needs to embrace the same technologies that are reshaping industry. “We need to recognise that this is the world our employers are in and if we don’t join that world we’ll be left behind. From our perspective, we’ve got to be running alongside the employers – if not running faster – if we want to help them in terms of their future skills”

3D printing a STEM skills solution

Talent 2050 report outlines new skills requirements

For Enginuity, this has meant investing in an internal data science capability which, Watson claims, has helped the organisation become much better placed to anticipate these emerging skills requirements. “We looked at how can we use the tools and techniques of industry 4.0 to create something quite special in the skills world,” she said.

Expanding on exactly how the organisation can help, Watson explained that it’s typically through a mixture of softer messaging – such as case studies on emerging engineers and the coverage generated by its annual awards competition – and more direct practical measures.

Here, Enginuity is particularly heavily involved in the apprenticeship arena, and along with partner organisation EAL (the awarding organisation for industry) is working closely with employers to help them develop their apprenticeship standards and also to refine the apprenticeship assessment regime. “Better data will only improve [these solutions] moving forward,” said Watson. “Making these solutions even more responsive to current and future needs, an even better user experience, and even easier to integrate and measure.”

Alongside apprenticeships, another priority area for the body is helping industry upskill existing employees, and it works with employers and skills bodies on the development training programmes to do just that. Whilst much of this is, inevitably, focused on the cutting edge technologies of Industry 4.0, Watson stressed that sometimes, improving an company’s digital awareness, can involve something as fundamental as ensuring that staff know how to use an Excel spreadsheet.

Another way in which the organisation hopes to move the skills dial is through a recently launched online apprenticeship matching service.

One major problem, frequently noted by The Engineer, is that whilst big name employers don’t typically struggle to attract the skills they require; less well-known, smaller companies do face significant challenges.

The Engineering Talent portal, which Enginuity has been piloting since April 2019, aims to address this by helping to funnel unsuccessful apprenticeship applications with larger companies through to SME recruiters. “The very large organisations are inundated with applications from young people for their apprenticeship vacancies,” said Watson. “BAE, one of the engineering talent partners, last year sent out 1300 rejection letters. At the other of the spectrum you’ve got the SME who may have a great opportunity but doesn’t have the brand name and can’t attract the young people”.

The skills sector’s not been great at collaboration in the past. It’s very fragmented.The future world gives the opportunity to bring a bit more strategy and structure to things

The new portal, which pulls in data from employers as well as all apprenticeship vacancies from the national apprenticeship service, points these unsuccessful applicants – many of whom would otherwise be lost to the engineering sector – at related opportunities elsewhere in the sector.

There’s no doubt that the blurring of boundaries between once distinct disciplines and sectors, and the widespread need for expertise in new emerging areas create some significant challenges for employers.

But, concluded Watson, it has also created the opportunity to be more strategic about skills, and to encourage both skills bodies, and the different engineering sectors to work together in a way that they haven’t before. “The skills sector’s not been great at collaboration in the past,” she said. “It’s very fragmented. There are something like 620 different initiatives focused on schools, and 36 professional engineering institutions. The future world gives the opportunity to bring a bit more strategy and structure to things.”

To this end, a key focus of the new organisation is encouraging the different skills working groups, and employers from different sectors to collaborate on the challenges they face.

“In the new digital world the skills that the aerospace, rail, and defence sectors need are becoming very common,” said Watson. “We’ve now got people like Network rail sitting on our board because they’re seeing that when they move into the world of digital railways the skillsets they need are more akin to the aerospace and defence sectors, skills they’ve never needed before. This creates the opportunity to get employers to collaborate, particularly on the data and digital skills agenda, and to work together, supported by Enginuity, on developing some of the digital skills solutions. We’re not going to see government come in with a lot of money for skills, so it’s very much down to the employers working together.”

Water Sector Talent Exodus Could Cripple The Sector

My local water company is Severn Trent which has a market capitalisation of £8.2 billion, made a pre-tax profit of £200 million in 2024 and is paying...