They say the best things in life are worth fighting for and that’s certainly a statement that Rowan Crozier, CEO of metal pressings and stamping specialist Brandauer, is fully aware of.

The Birmingham-based company, which is 156-years old in 2018, was struggling with an ageing workforce and the very real prospect of losing valuable toolmaking skills when older members of the team eventually retire.

The STEM ambassador knew the answer was to grow the firm’s own engineers, yet he still wore the visible scars of a failed apprenticeship programme that saw it invest in new talent only for JLR and TRW to poach them when they came of age. At one stage, he lost five in succession.

“We knew apprenticeships were the long-term answer, but we also knew it couldn’t be simply the same course or system that hadn’t worked in the past. There’s no point going over old ground in the hope that you get a different outcome,” explained Rowan.

“The question was how can we go from zero apprentices to ten in three years and retain a fair amount of them, I think 50% would have been considered a success. A Brandauer training academy was mooted, as was the potential to employ just graduates, neither of which really got off the ground.”

He continued: “After long and detailed discussions across all areas of the business we decided a more in-depth apprenticeship programme was the answer. We teamed up with In-Comm Training to be our provider of choice and then designed an in-house mentoring scheme and a schedule of learning that would see each young person spend time in different parts of the business.”

Four years on and the decision has definitely been worth it, with actual results far better than what the management team could ever have planned for.

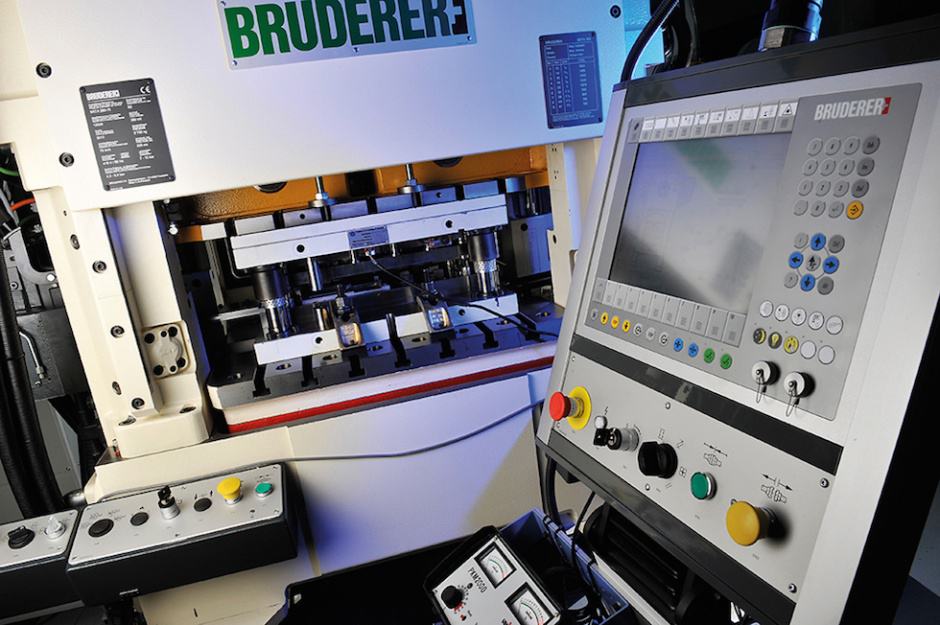

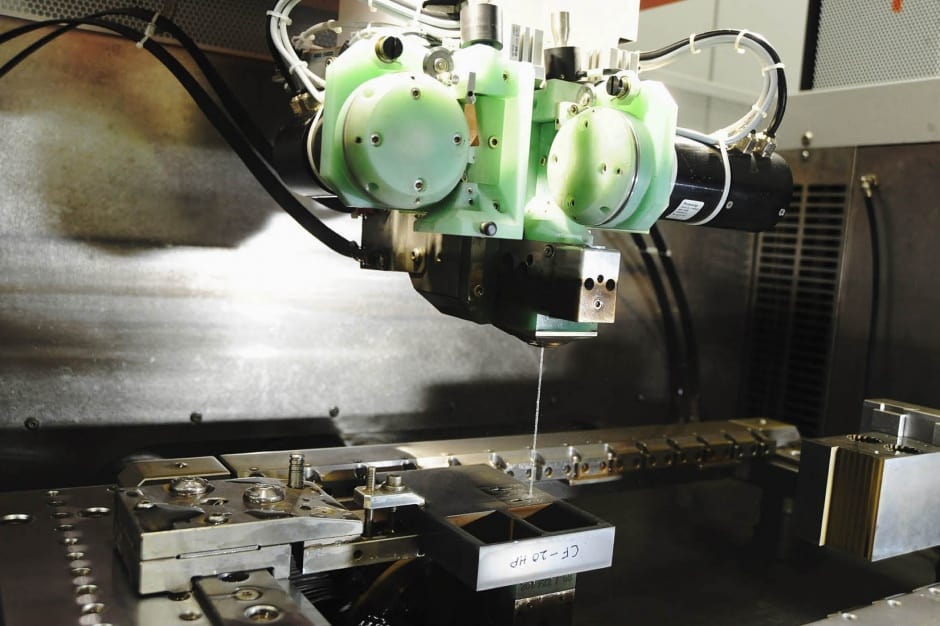

Brandauer puts its apprentices immediately to work

Three apprentices have qualified and are now working in quality assurance, new product introduction and continuous improvement, whilst 9 further budding engineers are currently at different stages of their development.

The Brandauer ‘average age’ has been reduced from 52 to 45 and valuable skills have been passed down by experts to the next generation. It has been one of the company’s biggest success stories and played a fundamental role in it moving from £7m annual sales to £8.8m this year.

“Spreading the maturity of the learners across the factory and not pigeonholing individuals to a department were key foundations of the scheme’s success,” added Rowan.

“The interview process also had a massive overhaul to allow for more efficient selection and recruitment of the right person. This is director-led with support from previous/current apprentices, making sure that when people start with us they understand what is expected of them, whilst ensuring all successful candidates grasp the entrepreneurial culture that is so important to our business.

“Giving existing staff mentoring training has also transformed our learner’s development journey. This covers technical aspects of the job, but more importantly pastorally.

“Mindfulness and positive mental health are one of the biggest challenges for young people coming into a pressurised environment. Our mentors are there to support them in their progression.”

Brandauer puts its apprentices immediately to work and this has seen the youngsters involved in the design and build of two complex progression tools and a number of live new product introductions.

They have also supported the quality team in planning for the transition to the IATF 16949 accreditation, so important for supplying the automotive sector.

“There is no limit to what our apprentices can achieve at the company. You only have to look at Stuart Berry, who joined us 10 years ago and is now our Manufacturing Director and a 1st class graduate of Birmingham City University – something we sponsored him for."

Rowan concluded: “I think the message I’m giving is simple…if you want a really great apprenticeship programme you have to invest 110% into it and shape it so that it suits your business. Anything less and you won’t deliver the same results for both the company and, perhaps more importantly, the talent you are trying to nurture.”

UK Enters ‘Golden Age of Nuclear’

The delay (nearly 8 years) in getting approval for the Rolls-Royce SMR is most worrying. Signifies a torpid and expensive system that is quite onerous...