Developed by researchers at RMIT University in Melbourne, Australia, the catalysts are claimed to be cost-effective to make and simple to scale.

The team’s lab demonstrations show the catalysts could potentially be used to power hypersonic flight while simultaneously cooling the system. The research is published in Chemical Communications.

Lead researcher Dr Selvakannan Periasamy said the work tackled one of the biggest challenges in the development of hypersonic aircraft, namely controlling the heat that builds up when planes fly at over five times the speed of sound.

“Our lab tests show the 3D printed catalysts we’ve developed have great promise for fuelling the future of hypersonic flight,” Periasamy said in a statement. “Powerful and efficient, they offer an exciting potential solution for thermal management in aviation - and beyond. With further development, we hope this new generation of ultra-efficient 3D printed catalysts could be used to transform any industrial process where overheating is an ever-present challenge.”

First author and PhD researcher Roxanne Hubesch said using fuel as a coolant is a promising experimental approach to the overheating problem.

“Fuels that can absorb heat while powering an aircraft are a key focus for scientists, but this idea relies on heat-consuming chemical reactions that need highly efficient catalysts,” Hubesch said. “Additionally, the heat exchangers where the fuel comes in contact with the catalysts must be as small as possible, because of the tight volume and weight constraints in hypersonic aircraft.”

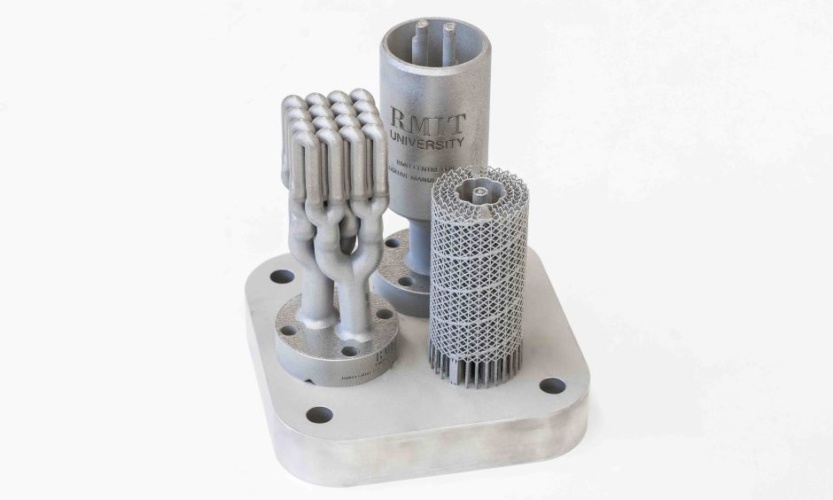

To make the new catalysts, the team 3D printed tiny heat exchangers made of metal alloys and coated them with zeolites.

The researchers replicated at lab scale the extreme temperatures and pressures experienced by the fuel at hypersonic speeds, to test the functionality of their design.

When the 3D printed structures heat up, some of the metal moves into the zeolite framework, a process RMIT said is crucial to the exceptional efficiency of the new catalysts.

“Our 3D printed catalysts are like miniature chemical reactors and what makes them so incredibly effective is that mix of metal and synthetic minerals,” Hubesch said. “It’s an exciting new direction for catalysis, but we need more research to fully understand this process and identify the best combination of metal alloys for the greatest impact.”

The next steps for the research team from RMIT’s Centre for Advanced Materials and Industrial Chemistry (CAMIC) include optimising the 3D printed catalysts by studying them with X-ray synchrotron techniques and other analysis methods.

The researchers also hope to extend the potential applications of the work into air pollution control for vehicles and miniature devices to improve indoor air quality.

Fuel cell-based system converts atmospheric CO2 into usable electric current

In any event, splitting water into hydrogen and oxygen requires energy, so in this process it is the potential chemical energy of sodium metal that...