3M collects TechAmerica award for cut and grind material

Engineers at 3M have picked up the TechAmerica Foundation’s American Technology Award in the manufacturing category for the development of the company’s Cubitron II cutting and grinding material.

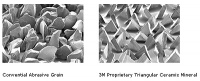

Cubitron II is made from triangular-shaped ceramic grains, electrostatically oriented with their cutting edges facing the work surface to form sharp peaks, each acting like individual cutting tools that wear evenly. As the triangular-shaped grains wear, they continuously fracture to form sharp points and edges.

Robert Cowan, manufacturing technology manager for 3M Abrasive Systems Division, accepted the award on the company’s behalf, noting that industrial metal fabricators using Cubitron II-based products are reporting productivity gains in ranges of up to 100 per cent or more, underscoring the fact that products (such as disks and belts) made from the material decrease friction and result in cooler workpiece temperatures.

’This helps to eliminate burnishing, oxidation and discolouring while producing fewer heat-related stress cracks in high-cost end parts, including implantable medical orthopaedic devices,’ Cowan said.

3M has 16 pending patents with the US Patents and Trademark Office on the Cubitron II technology.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Breaking the 15MW Barrier with Next-Gen Wind Turbines

Hi Martin, I don´t have any detailed parameters for the 15MW design other than my reading of the comment in the report ´aerodynamic loads at blade-tip...