AtkinsRéalis expands role on UKAEA tritium facility

The UK Atomic Energy Authority (UKAEA) has appointed AtkinsRéalis to lead the design of a core component of a new tritium research centre to enable sustainable fusion.

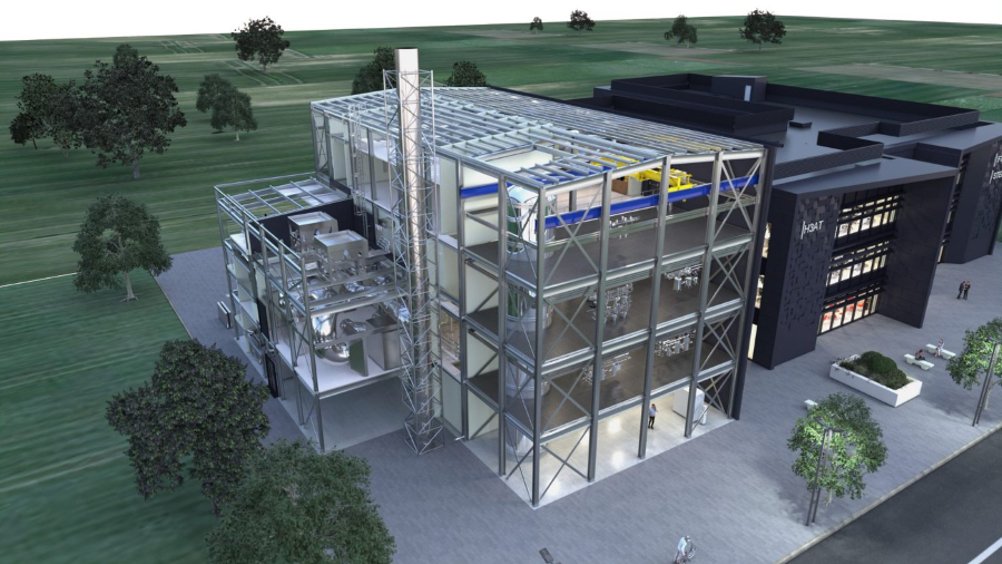

The Isotype Separation System will form part of UKAEA’s Hydrogen-3 Advanced Technology (H3AT) Facility, currently under construction at UKAEA’s Culham Campus in Oxfordshire based on designs delivered by AtkinsRéalis. Claimed to be a world-first, H3AT is a tritium fuel cycle research facility that will include a prototype-scale process plant and experimental platform, which is a scaled version of the design for ITER, the world’s largest experimental fusion project.

Since tritium is practically non-existent in nature, a fusion power plant must breed its own tritium using the neutron produced in the fusion reaction and the light metal lithium, generating one tritium and one helium nucleus. According to AtkinsRéalis, the tritium capacity of the complex Isotope Separation System will make it the most advanced research facility of its kind, helping to enable the development of tritium infrastructure necessary for sustainable fusion power.

“The H3AT Facility will be a first-of-a-kind research facility to strengthen UK and international efforts to advance tritium fuel cycle technology,” said Jason Dreisbach, head of Advanced Energy Technologies at AtkinsRéalis.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...