Autodesk unleash future of manufacturing at MACH 2018

The Autodesk stand at MACH 2018 offered visitors a tantalising glimpse into the ways in which software can drive machines to increase efficiency and productivity whilst pushing down costs.

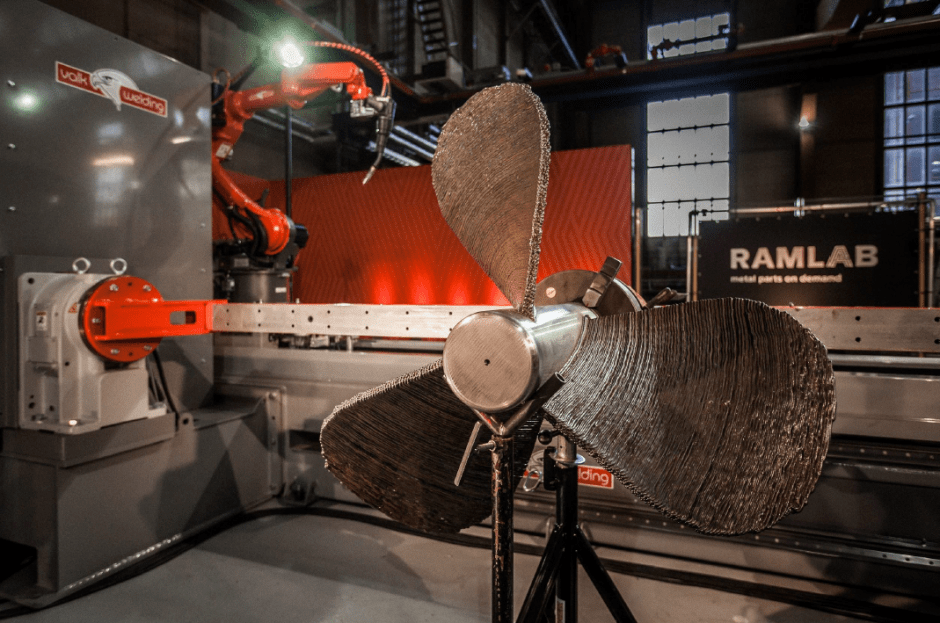

The company’s collaboration with The Port of Rotterdam's Additive Manufacturing Fieldlab (RAMLAB) is a prime example of how Autodesk is helping to solve a costly problem whilst simultaneously giving its customer a commercial advantage.

Robin Smith, Pre-Sales Applications Manager – Autodesk told The Engineer that it can cost $1m per day for a large container vessel to stay in port whilst a replacement is found for a damaged propeller.

Smith explained that Autodesk is helping the Port of Rotterdam in its ambition to build replacement parts on site using directed energy deposition. Smith said the solution is effectively PowerMill with a robot and additive tool kit plugged into it, driving the robot with a welding gun on the end of it, laying down material.

“Once it’s been laid out it can then be subtractively removed by milling it away to arrive at the final shape,” he said. “Again, it’s a really interesting technology – a combination of additive and subtractive working with robots. The goal is a production cell for them where they can actually do this.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Breaking the 15MW Barrier with Next-Gen Wind Turbines

The key point s that wind power is intermittent. There is a lot of crowing when it is the main source of power generation but things fall silent when...