Automated tool system could enhance efficiency in hospitals

Technologies used to automate manufacturing processes are to be employed in hospitals in order to track and manage surgical tools.

This is the aim of scientists at GE Global Research, who are working with GE Healthcare and the US Department of Veteran’s Affairs (VA) to develop a prototype system capable of locating, sorting, delivering, and sterilising surgical tools with little oversight.

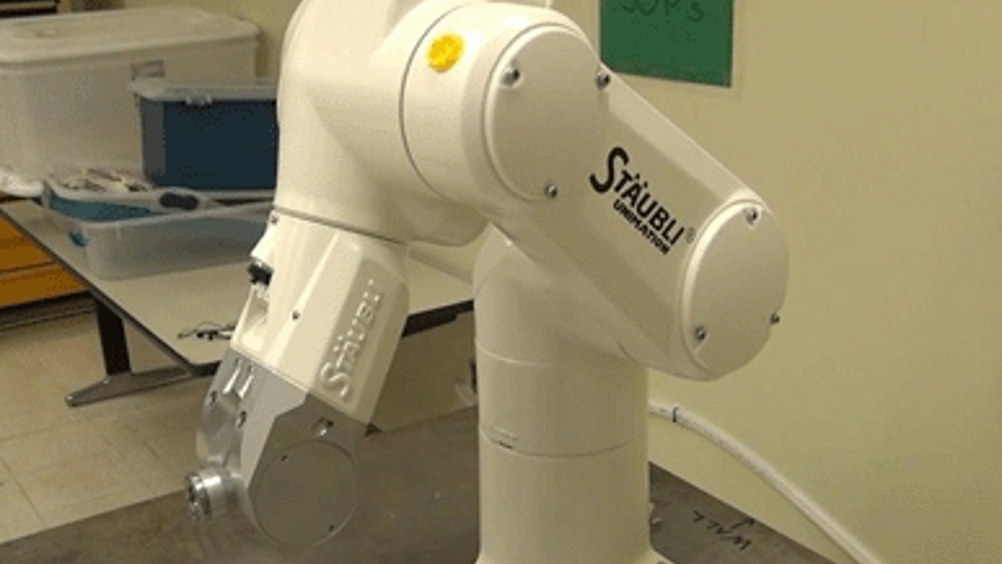

Industrial internet, robotic systems, RFID, and computer vision will form the backbone of the automated system. Tools such as clamps and scalpels will be provided a unique ID so that they are readily identifiable by various robotic components.

The prototype system will perform tasks including kitting of surgical tools, movement throughout the sterilisation process, and transport to and from the operating theatre ensuring the correct tools are in the right place, at the right time, and in sterile and working order.

‘The technologies we’re investigating have been used to automate manufacturing processes… for years, and we believe they, in combination with a new level of intelligence, can have a substantial impact in hospitals,’ said Lynn DeRose, principal investigator and Auto-ID technology expert in the Distributed Intelligent Systems Lab at GE Global Research.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Breaking the 15MW Barrier with Next-Gen Wind Turbines

The key point s that wind power is intermittent. There is a lot of crowing when it is the main source of power generation but things fall silent when...