Bio-mineral production uses less energy than ceramics

A new crop of high-performance bio-minerals is being created by a research group at Leeds University using a fraction of the energy required in current ceramics manufacture.

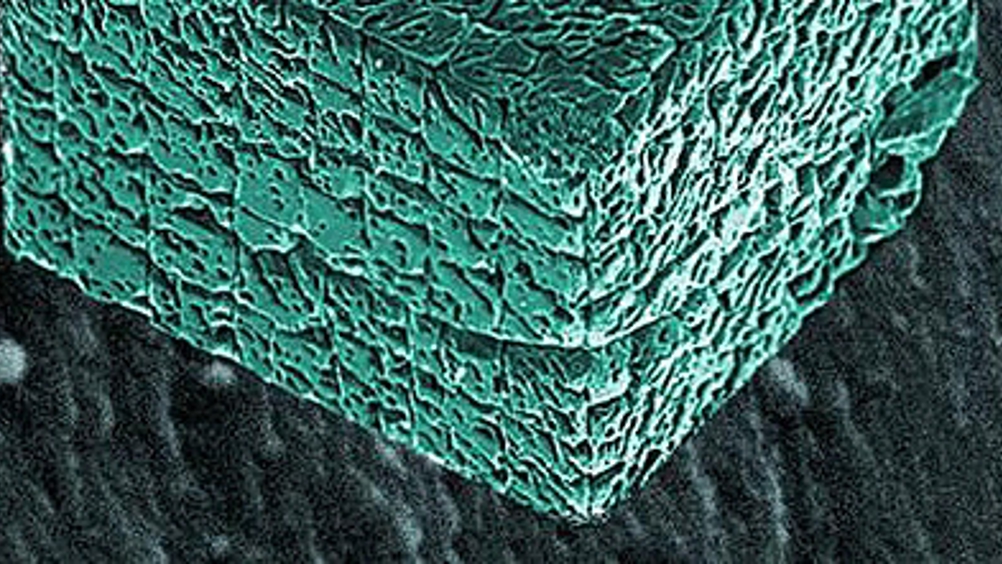

Inspiration for the materials comes from biological minerals of the sort found in seashells, which can rival ceramics in terms of hardness and mechanical properties but are created in aqueous environments at ambient temperatures.

‘With calcium carbonate, if it’s a pure geological sample you simply have to tap it with a hammer and it will fall apart along the cleavage planes,’ said Prof Fiona Meldrum of Leeds University. ‘But if you do this to a biogenic calcite crystal it fractures with extreme difficulty.’

The key feature of bio-minerals is that they are composites, made from an inorganic mineral such as calcium carbonate, with a small amount (often only 0.1 per cent by weight) of organic material, usually a protein.

‘You still have a perfect single crystal but inside this crystal you find these proteins. Quite how they are included in the structure isn’t well understood but it makes an enormous difference to the properties.’

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

BEAS funding available to help businesses cut energy costs

And not a moment too soon, if the following exchange broadcast last Friday 13th June, on the Radio 4 ´Rare Earth´ program (link below, ~ 17 minutes...