Bipolymers help convert waste heat to electricity

German cleantech startup Poligy claims its new Bipolymers technology could help unlock the huge untapped value in waste heat.

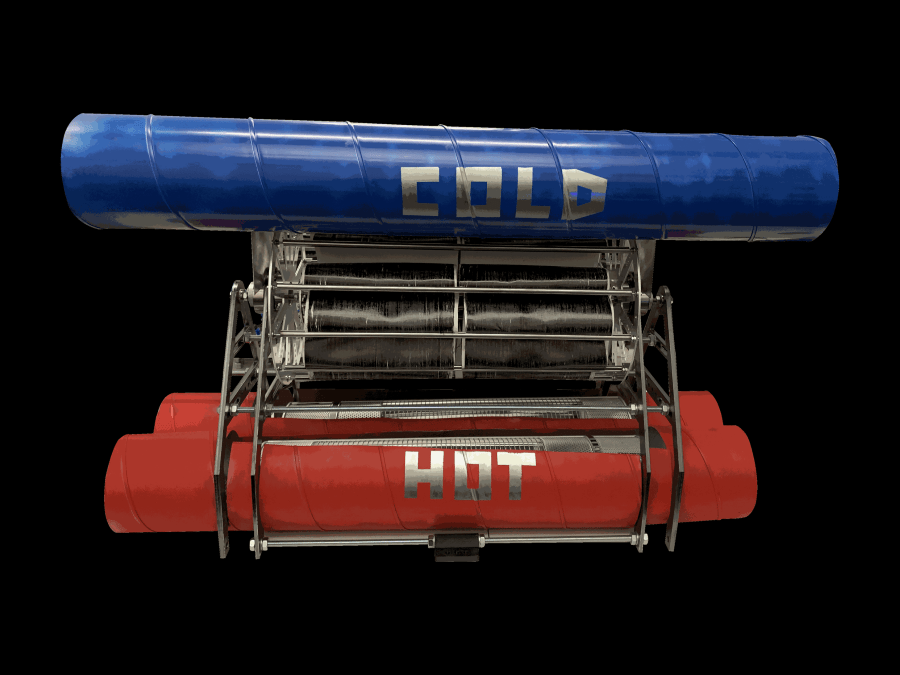

Developed by chemist and company co-founder Martin Huber, Bipolymers are two-ply plastic strips that form a wheel or band in thermal engines and solar modules. The plastic strips contract and expand depending on temperature, creating a movement in the wheel or belt which then generates electricity.

According to a recent study conducted by Global Market Insights, the global waste heat market will grow from $40bn in 2018 to more than $80bn by 2025. Around half of all waste heat goes completely unused, one of the reasons being the need to either utilise it immediately or spend money converting it to electricity. Poligy says that Bipolymers can convert solar and industrial waste heat into electricity at a cheaper cost than any previous technology.

“Until now, there has been no cheap technology alternative that can produce green electricity from waste heat at temperatures between 50° Celsius and 200° Celsius. In addition, the thermal engines and Bipolymers can be produced in large quantities and at low cost," explains Huber.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Comment: The UK is closer to deindustrialisation than reindustrialisation

"..have been years in the making" and are embedded in the actors - thus making it difficult for UK industry to move on and develop and apply...