Compact hydrogen storage gets a boost

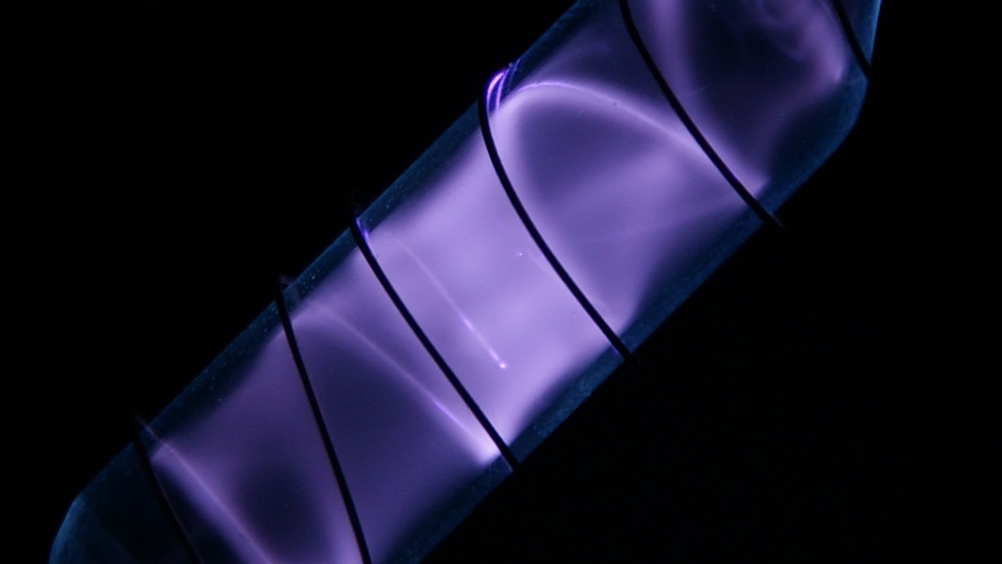

An international team of researchers has used nano-engineering to speed up the charge and recharge cycle of compact, solid-state hydrogen storage materials.

Solid metal hydrides are seen as a potential fuel source for powering hydrogen vehicles, but are usually limited by slow hydrogen uptake and release. But scientists from Lawrence Livermore National Laboratory (LLNL), working with colleagues from Sandia National Laboratories, Thailand’s Mahidol University, and the National Institute of Standards and Technology, have developed a technique to overcome this.

The researchers found that nanoconfinement - infiltrating the metal hydride within a matrix of another material such as carbon – can have the effect of shortening the diffusion pathways for hydrogen, making the hydride a more efficient fuel source. Using a high-capacity lithium nitride (Li3N) hydrogen storage system under nanoconfinement, they also discovered that internal ‘nano-interfaces’ could alter the phases produced when the material is cycled, further boosting performance. The research is reported in the journal Advanced Materials Interfaces.

"The key is to get rid of the undesirable intermediate phases, which slow down the material's performance as they are formed or consumed,” said Brandon Wood, an LLNL materials scientist and lead author of the paper. “If you can do that, then the storage capacity kinetics dramatically improve and the thermodynamic requirements to achieve full recharge become far more reasonable."

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

UK Automotive Feeling The Pinch Of Skills Shortage

Aside from the main point (already well made by Nick Cole) I found this opinion piece a rather clunking read: • Slippery fish are quite easy to...