The project partners will work together to further develop and validate CSIRO’s MagSonic technology, which is said to produce magnesium using up to 80 per cent less energy and up to 60 per cent less carbon dioxide emissions thanks to its supersonic nozzle.

Once the technology is ready for commercialisation, Enirgi Group will have the option to take up an exclusive global license that would see the company initially build a commercial-scale magnesium production facility in Australia.

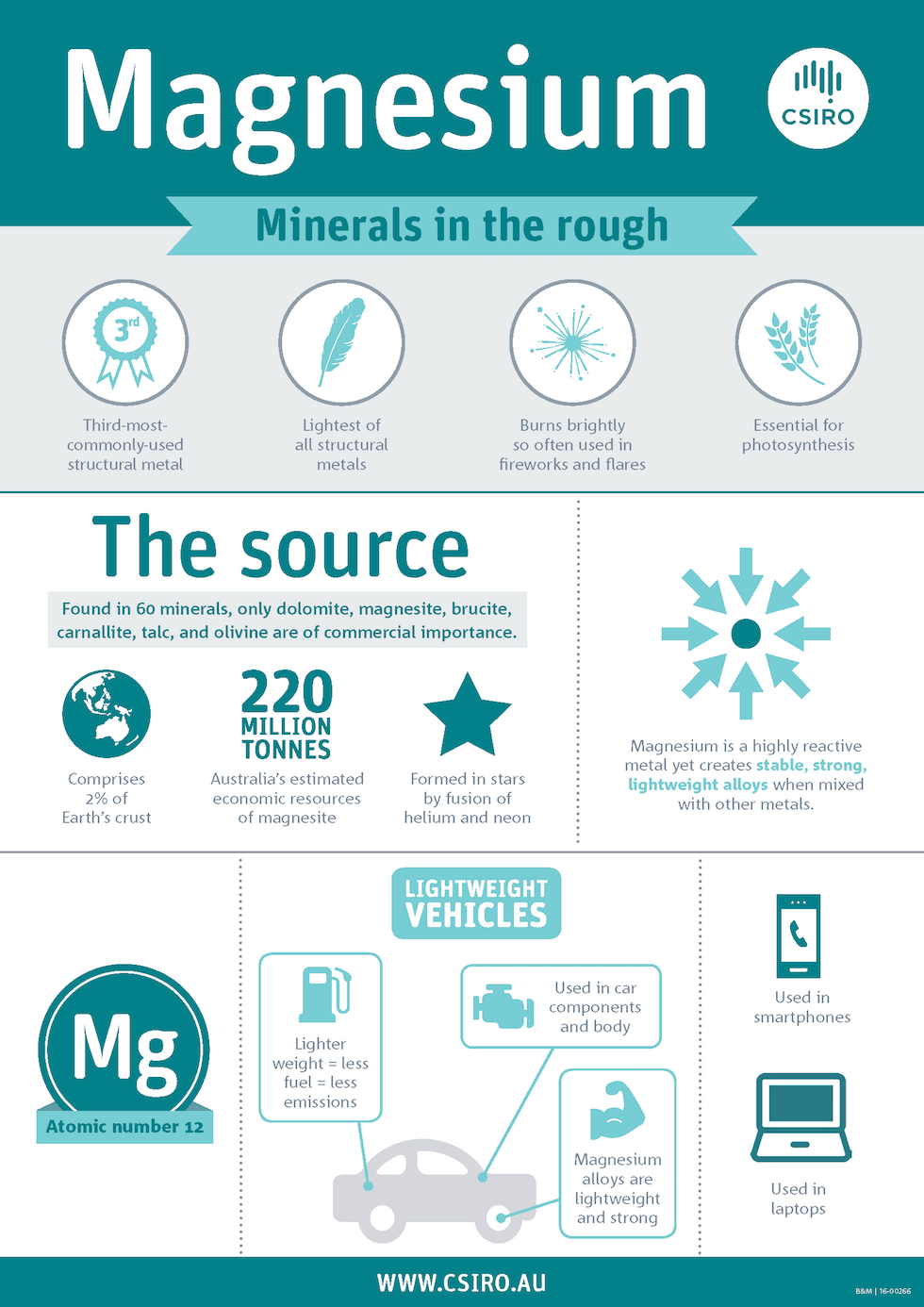

Demand for magnesium is rising from car manufacturers who are turning to the metal as a solution for making lightweight, low-emission vehicles.

Dr Mark Cooksey, who leads CSIRO's sustainable process engineering group, said commercialisation of MagSonic would help take advantage of Australia's abundant reserves of magnesite ore that remain largely untapped.

"The growth of magnesium use has been limited because it's been too expensive and labour intensive to produce the metal from ore using traditional processes," Dr Cooksey said in a statement. "Our MagSonic technology offers an economically-viable solution to overcome these issues and make clean magnesium more available and affordable to manufacturers.”

According to CSIRO, MagSonic uses carbothermal reduction and a supersonic nozzle to produce high quality magnesium. It involves heating magnesia with carbon to extreme temperatures to produce magnesium vapour and carbon monoxide.

The vapour and carbon monoxide are passed through a supersonic nozzle at four times the speed of sound to cool the gases in milliseconds, condensing and solidifying the magnesium vapour to magnesium metal.

"We are confident that this process is capable of commercial production,” said Anthony Deal, Enirgi Group's vice president of corporate development. "The flow-through benefits to emerging industries like electric vehicle manufacturing are enormous, not to mention a substantial reduction in carbon emissions when compared to current magnesium production processes.”

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...