More in

Direct-ink-writing creates glucose biosensor with less waste

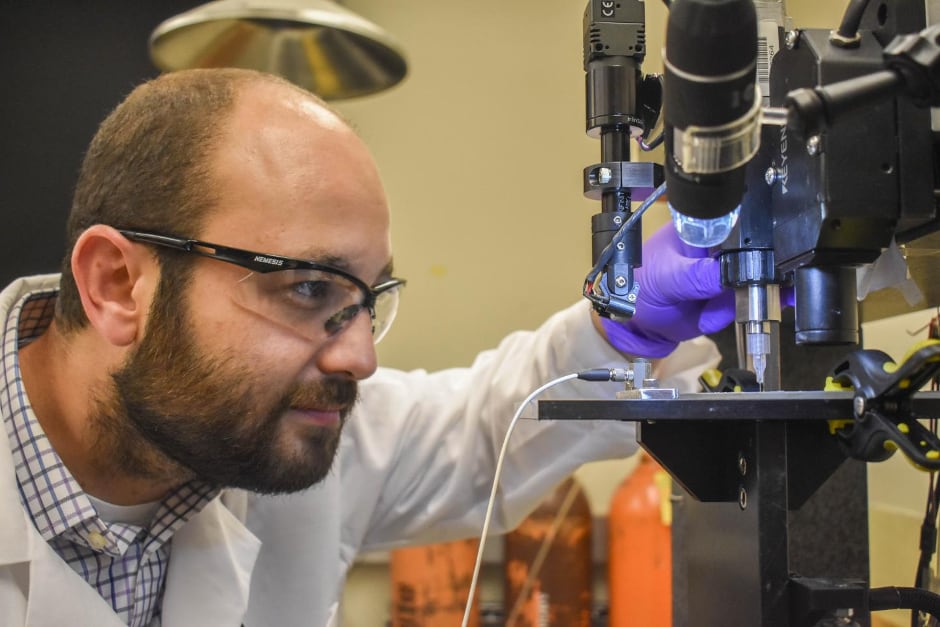

Researchers have used direct-ink-writing to create a 3D‑printed glucose biosensor for use in wearable monitors, an advance in manufacturing that overcomes current issues around waste and cleanroom processing.

The work by Washington State University researchers could lead to improved glucose monitors for millions of people living with diabetes.

Led by Arda Gozen and Yuehe Lin, faculty in the School of Mechanical and Materials Engineering, the research has been published in the journal Analytica Chimica Acta.

Diabetics commonly monitor their condition with glucose meters that require constant finger pricking. Continuous glucose monitoring systems are an alternative but are not cost effective.

According to WSU, researchers have been working on wearable, flexible electronics that conform to patients’ skin and monitor glucose in bodily fluids. To build such sensors, manufacturers have used photolithography or screen printing. Whilst effective, these methods create a lot of waste and require the use of harmful chemicals and expensive cleanroom processing.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

National Gas receives funding to develop Gravitricity underground hydrogen storage system

One single rock salt mine - Winsford - has 23 <i>MILLION </i>cubic metres of void and even allowing for 10% of that void set aside for hazardous waste...