Discarded silicon aids creation of flexible battery components

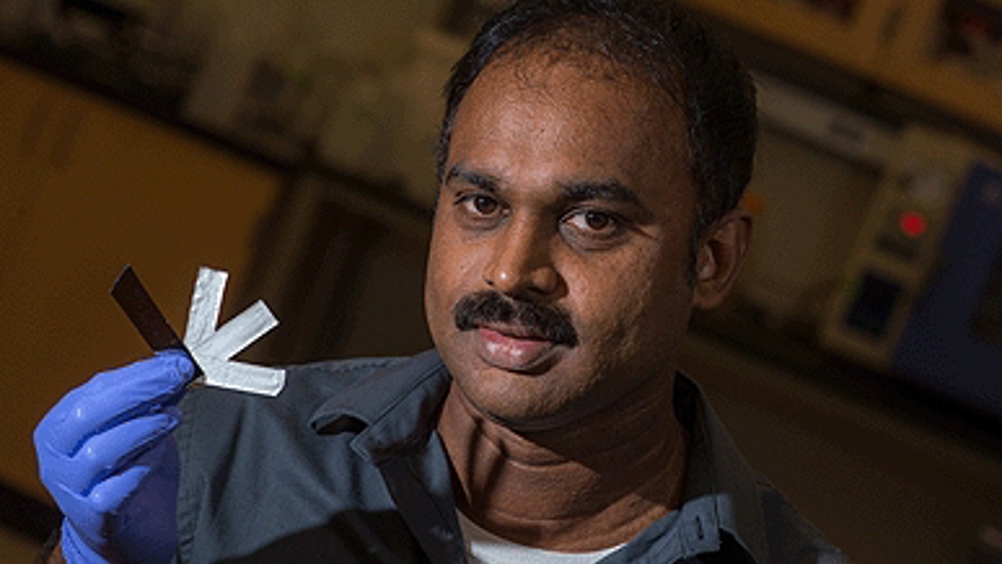

Researchers at Rice University and the Université catholique de Louvain, Belgium, have developed a way to make flexible components for rechargeable lithium-ion (Li-ion) batteries from discarded silicon.

Rice lab of materials scientist Pulickel Ajayan created forests of nanowires from silicon, which absorbs 10 times more lithium than the carbon commonly used in Li-ion batteries. However, because it expands and contracts as it charges and discharges, it breaks down quickly.

The Ajayan lab has reported this week in the journal Proceedings of the National Academy of Science on its technique to make carefully arrayed nanowires encased in electrically conducting copper and ion-conducting polymer electrolyte into an anode. The material is said to give nanowires the space to grow and shrink as needed, which prolongs their usefulness. The electrolyte also serves as an efficient spacer between the anode and cathode.

Transforming waste into batteries should be a scalable process, said Ajayan, Rice’s M and Mary Greenwood Anderson professor in mechanical engineering and materials science and of chemistry. In a statement, the researchers said they hope their devices are a step towards a new generation of flexible, efficient, inexpensive batteries that can conform to any shape.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

My local water company is Severn Trent which has a market capitalisation of £8.2 billion, made a pre-tax profit of £200 million in 2024 and is paying...