FastBlade composites stress test facility opens for business

Composite tidal turbine blades can now be stress tested at FastBlade, a new facility opened today (May 13) in Rosyth that will speed up the development of marine energy technologies.

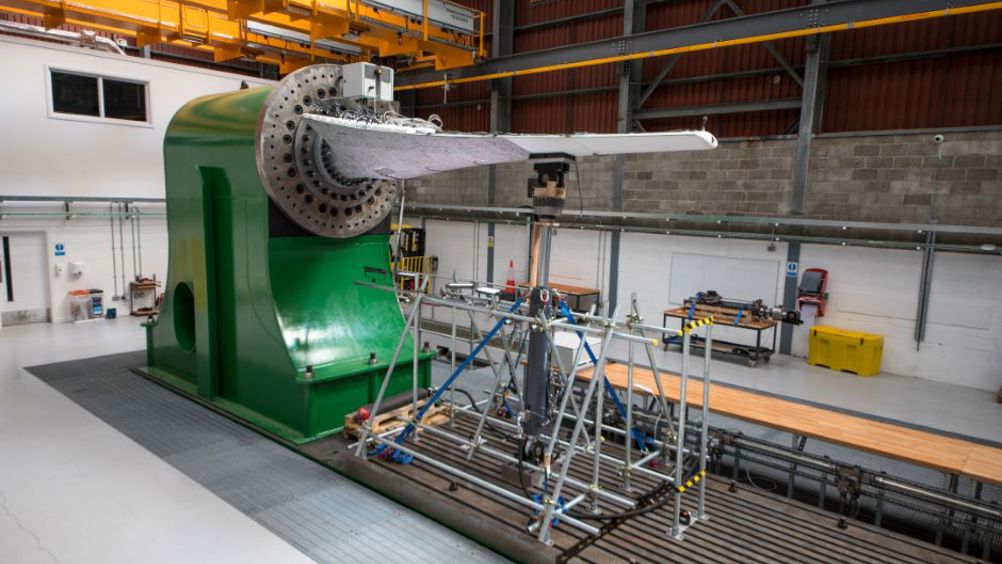

In under three months FastBlade - a partnership between Edinburgh University and Babcock International - will simulate the stresses placed on tidal turbine blades during two decades at sea. To do so, Fastblade’s 75-tonne reaction frame will exert powerful forces on turbine blades over 50 feet long via a system of hydraulic cylinders.

In doing so, it will replicate the complex forces to which tidal turbines are exposed at sea using digital and hydraulic technology systems developed by engineers at Edinburgh University.

In a statement, Professor Conchúr Ó Brádaigh, head of School of Engineering at Edinburgh University, said: “FastBlade will be the world’s first dedicated fatigue test facility for tidal turbine blades, and will help this emerging industry provide clean, reliable renewable energy at a reasonable cost to consumers.

“The facility will also help maintain the globally leading position of Scottish tidal turbine developers in the race to find sources of clean and secure power, as well as confirming the societal impact of Edinburgh University’s research and development efforts in marine renewable energy.”

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

UK Enters ‘Golden Age of Nuclear’

The delay (nearly 8 years) in getting approval for the Rolls-Royce SMR is most worrying. Signifies a torpid and expensive system that is quite onerous...