Flexible wearable device harvests thermal energy

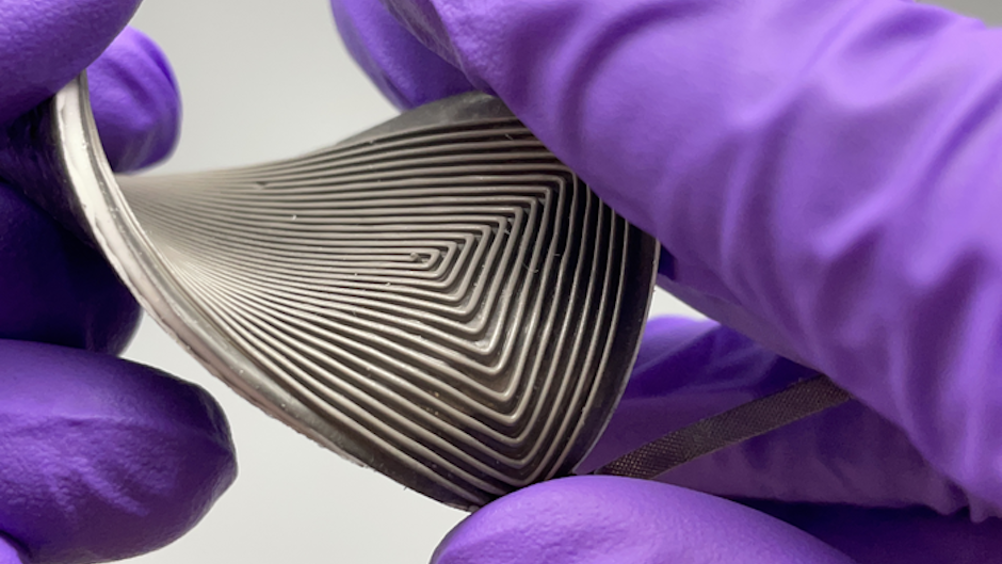

Researchers in the US have developed a flexible thermoelectric wearable device that converts body heat to electricity.

The team, from University of Washington, published its research in Advanced Energy Materials. The device is described as soft and stretchable, yet sturdy and efficient.

“It’s a 100 per cent gain if we harvest thermal energy that would otherwise be wasted to the surroundings,” said Mohammad Malakooti, a UW assistant professor of mechanical engineering. “Because we want to use that energy for self-powered electronics, a higher power density is needed.

“We leverage additive manufacturing to fabricate stretchable electronics, increase their efficiency and enable their seamless integration into wearables while answering fundamental research questions.”

According to the team, the device remains fully functional after more than 15,000 stretching cycles at 30 per cent strain — a highly desirable feature for wearable electronics and soft robotics. Researchers also found that it showed a 6.5 times increase in power density compared to previous stretchable thermoelectric generators.

To create the flexible devices, the researchers 3D printed composites with engineered functional and structural properties at each layer. The filler material contained liquid metal alloys, which provide high electrical and thermal conductivity. The team said that the alloys address limitations in previous devices, including an inability to stretch, inefficient heat transfer and a complex fabrication process.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...