Fluid-like behaviour of sliding metals could aid durability

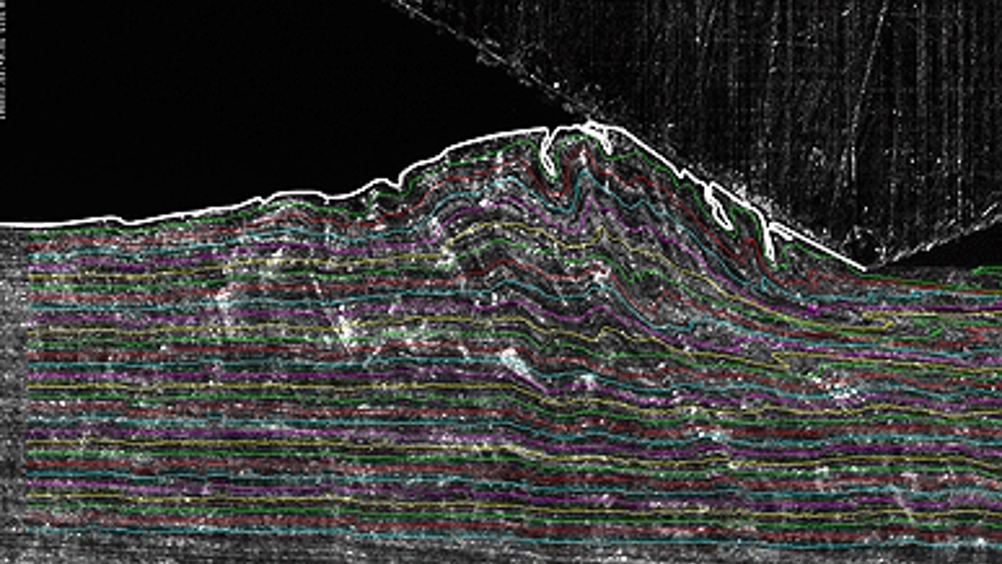

Researchers have discovered a swirling, fluid-like behaviour in a solid piece of metal sliding over another, providing new insights into the mechanisms of wear and generation of machined surfaces.

Studies using a microscope and high-speed camera are said to have revealed the formation of bumps, folds, vortex-like features and cracks on the metal surface. The experiment was conducted at room temperature and the sliding conditions did not generate enough heat to soften the metal.

‘We see phenomena normally associated with fluids, not solids,’ said Srinivasan Chandrasekar, a Purdue University professor of industrial engineering who is working with postdoctoral research associates Narayan Sundaram and Yang Guo.

Many mechanical parts, from bearings to engine pistons, undergo such sliding.

‘It has been known that little pieces of metal peel off from sliding surfaces,’ Chandrasekar said. ‘The conventional view is that this requires many cycles of rubbing, but what we are saying is that when you have surface folding you don’t need too many cycles for these cracks to form. This can happen very quickly, accelerating wear.’

According to a statement, the researchers are developing models to further study the phenomena and understand the wide-ranging consequences of such fluid-like flow in metals, Chandrasekar said. The findings might also lead to improved surface quality in materials processing.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

My local water company is Severn Trent which has a market capitalisation of £8.2 billion, made a pre-tax profit of £200 million in 2024 and is paying...