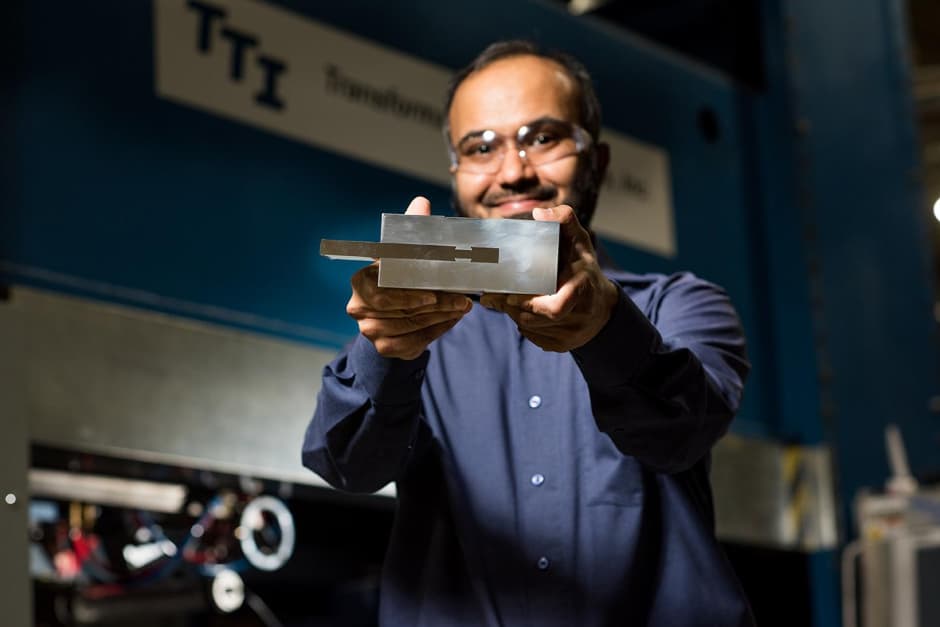

Joining technique dovetails steel and aluminium for military vehicles

A process for joining thick plates of aluminium to steel could to lead to lighter-weight military vehicles that are more agile and fuel efficient.

The process – dubbed Friction Stir Dovetailing – was developed by researchers at Pacific Northwest National Laboratory and is described in Scripta Materialia.

According to the US Government Accountability Office, the military spends several billion dollars each year on fuel consumption. To lower fuel costs and increase operational effectiveness the US Army Tank Automotive Research Development and Engineering Center (TARDEC) launched a campaign in 2014 seeking ways to make combat systems more lightweight. One approach looked at the replacement of heavy steel components with thicker aluminium, which cannot be welded to steel due to the vastly different melting points of the two metals.

In a bid to overcome this hurdle, TARDEC teamed up with PNNL to develop Friction Stir Dovetailing. Previous techniques had included Friction Stir Welding to join similar metals of differing thickness, and Friction Stir Scribe, which joins thin sheets of different materials, like aluminium and steel.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

UK Enters ‘Golden Age of Nuclear’

The delay (nearly 8 years) in getting approval for the Rolls-Royce SMR is most worrying. Signifies a torpid and expensive system that is quite onerous...