Solar cells made from perovskite have potential as a replacement for silicon solar cells as they are relatively efficient and can be made economically. They do, however, decompose when they react with moisture and oxygen or when they are exposed to light, heat, or used for an extended time. This has raised concerns that the small amount of lead present in perovskite solar cells could pollute the environment.

The lead comes from the perovskite material and a compound used to make a perovskite solar cell’s capping layer.

Now, research by scientists from Nanyang Technological University, Singapore (NTU Singapore) and the Institute of Materials Research and Engineering (IMRE) at the Agency for Science, Technology and Research (A*STAR) have provided the possibility of capping materials based on non-toxic metals.

Their study, published in Nature Energy and led by Professor Sum Tze Chien, director of the Institute of Advanced Studies at NTU and Associate Dean (Research) of NTU’s College of Science, and Professor Lam Yeng Ming, Chair of NTU’s School of Materials Science and Engineering, could bring perovskite solar cells closer to market.

Layers

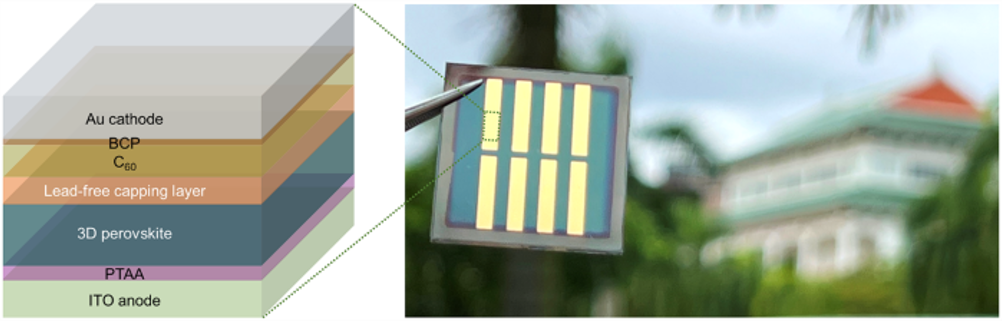

Perovskite solar cells are made of several layers of materials, including a perovskite layer that harvests light and the capping layer. The capping layer is coated onto the perovskite layer to protect the solar cell from environmental stresses, and to boost the performance of the cell.

To ensure that the capping layer is compatible with the underlying perovskite layer, researchers typically use a so-called half precursor (HP) method to fabricate it. One of the precursor chemicals is first deposited on top of the perovskite layer which provides the other precursor. Through a cation exchange reaction, the deposited precursor reacts with lead ions present in the perovskite layer beneath to form a lead-based chemical compound that makes up the capping layer.

To make perovskite solar cells more environmentally friendly, the NTU scientists devised an approach called a full precursor (FP) solution method, to synthesise a capping layer without lead.

Using the FP method, the scientists coated perovskites with solutions containing metal halide salts and phenethylammonium iodide (PEAI) that is applied to perovskites to improve cell performance.

The researchers found that a zinc-based compound PEA2ZnX4 synthesised using the method was the most effective capping material among the other materials tested.

To fabricate a solar cell capped with PEA2ZnX4, the researchers first dissolved zinc halide salts and PEAI in acetonitrile. They then deposited the solution onto a rapidly-spinning perovskite layer attached to an electrically conductive glass substrate to form a thin and uniform layer. The coated perovskite was heated at 100oC for 10 minutes to bind the capping layer to the surface of the perovskite. The researchers then used vacuum evaporation to synthesise the other layers of the perovskite solar cell.

Using the FP method, the scientists created a 1” x 1” prototype solar cell capped with the zinc-based compound.

Zinc

The scientists examined the zinc-based capping layer using electron microscopy and spectroscopy and found that it did not affect the electrical properties of the underlying perovskite layer. The capping layer also helped to cover defects on the surface of the perovskite layer and improved its light-harvesting capabilities.

“By enabling zinc and other non-toxic metals to be used in the capping layer, our innovation potentially solves a major obstacle that prevents the widespread use of perovskite solar cells,” said Dr Ye Senyun, research fellow from NTU’s School of Physical and Mathematical Sciences, one of the lead researchers of the study.

The researchers found that the fabricated solar cell was as effective at converting sunlight as conventional perovskite solar cells. In experiments, the solar cell could convert 24.1 per cent of the light captured to electricity, close to the highest efficiency achieved by perovskite solar cells to date.

Related content

The prototype is also said to have demonstrated good reproducibility, with an average light conversion rate of almost 23 per cent over 103 cells tested. It had a long lifespan, maintaining more than 90 per cent of its ability to convert light into electricity for more than 1,000 hours of operation at full capacity.

The performance of the device was also more stable at high temperatures compared to devices without a capping layer.

“By expanding the library of materials that can be used, our findings unlock new opportunities for developing superior materials for the capping layer, for more efficient and stable perovskite solar cells,” said Prof Sum. “This lead-free protective capping method can also be extended to other applications like perovskite light emitting devices, lasers and detectors.”

The scientists are working on scaling up the method to fabricate full-sized solar cells. They are also in the process of filing a patent.

Hard hat mounted air curtain adds layer of protection

Something similar was used by miners decades ago!