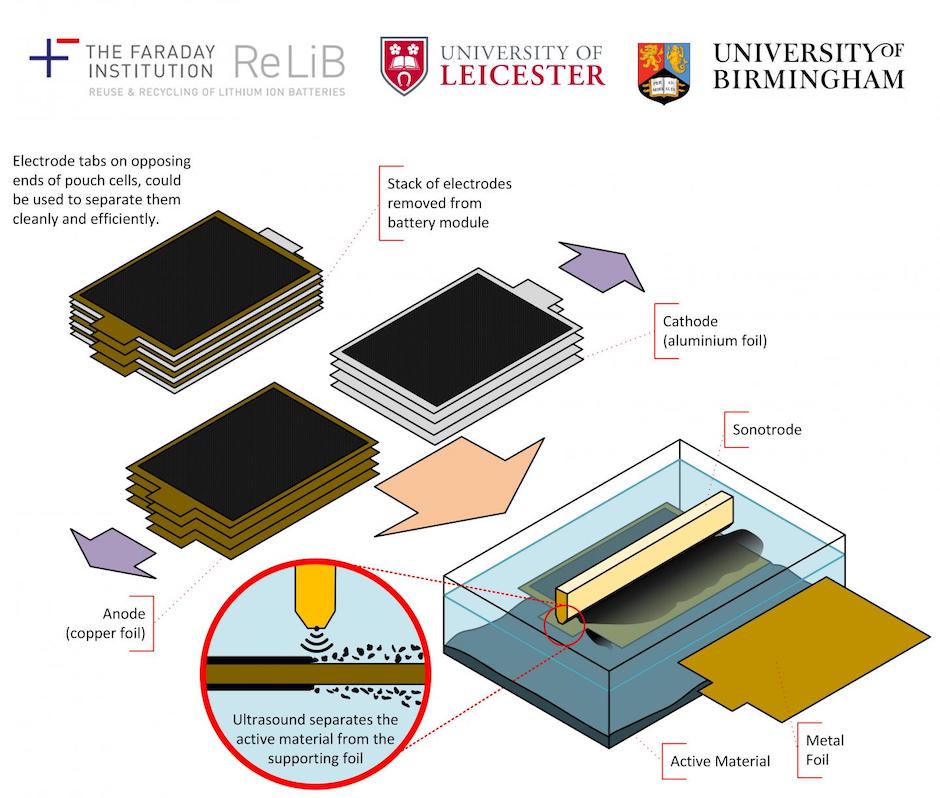

The method has been developed with the Faraday Institution to tackle recycling of electric vehicle (EV) batteries. Leicester University's Professor Andy Abbott, project leader, compared the process to the way in which a dentist’s ultrasonic descaler works, breaking down adhesive bonds between the coating layer and substrate.

“This novel procedure is 100 times quicker and greener than conventional battery recycling techniques and leads to a higher purity of recovered materials,” he said in a statement.

Current methods for lithium-ion battery recycling usually involve feeding end-of-life batteries into a shredder or high-temperature reactor, with a complex set of physical and chemical processes required to produce useable materials.

Birmingham battery recycling facility completed

UK risks losing out in automotive lithium ion battery recycling market

If end-of-life batteries are disassembled rather than shredded, there is potential to recover more material in a purer state. Disassembly of lithium-ion batteries has been shown to recover around 80 per cent of the original material.

Separating critical materials such as lithium, nickel, manganese and cobalt from used batteries quickly and in an environmentally-friendly way has typically been a challenge. The new project aims to solve this by adapting technology widely used in the food preparation industry.

The team has applied for a patent for the ultrasonic delamitation technique, which blasts the active materials required from the electrodes leaving virgin aluminium or copper. Published in Green Chemistry, the results were said to be ‘highly effective’ in removing graphite and lithium nickel manganese cobalt oxides.

Professor Pam Thomas, CEO at the Faraday Institution commented: “For the full value of battery technologies to be captured for the UK, we must focus on the entire life cycle — from the mining of critical materials to battery manufacture to recycling — to create a circular economy that is both sustainable for the planet and profitable for industry.”

Researchers said they tested the technology on four most common battery types and are now in discussions with battery manufacturers and recycling companies to place a technology demonstrator at an industrial site in 2021, with longer-term aims to license the technology.

Poll: Should the UK’s railways be renationalised?

The term innovation is bandied about in relation to rail almost as a mantra. Everything has to be innovative. There is precious little evidence of...