Liquid film-coated material has industrial potential

A team of researchers at the Wyss Institute at Harvard University and Harvard’s School of Engineering and Applied Sciences (SEAS) are designing a new kind of adaptive material with tuneable transparency and wettability features.

Described in the online version of Nature Materials, the new material could enable highly precise, self-adjusting contact lenses that clean themselves, or pipelines that optimise the rate of flow depending on the volume of fluid coming through them and the environmental conditions outside.

‘The beauty of this system is that it’s adaptive and multifunctional,’ said senior author Joanna Aizenberg, PhD, a Core Faculty member at the Wyss Institute and the Amy Smith Berylson Professor of Materials Science at SEAS.

The new material was inspired by dynamic, self-restoring systems in nature, such as the liquid film that coats eyes. Individual tears join up to form a dynamic liquid film with an obviously significant optical function that maintains clarity, while keeping the eye moist, protecting it against dust and bacteria, and helping to transport away any wastes.

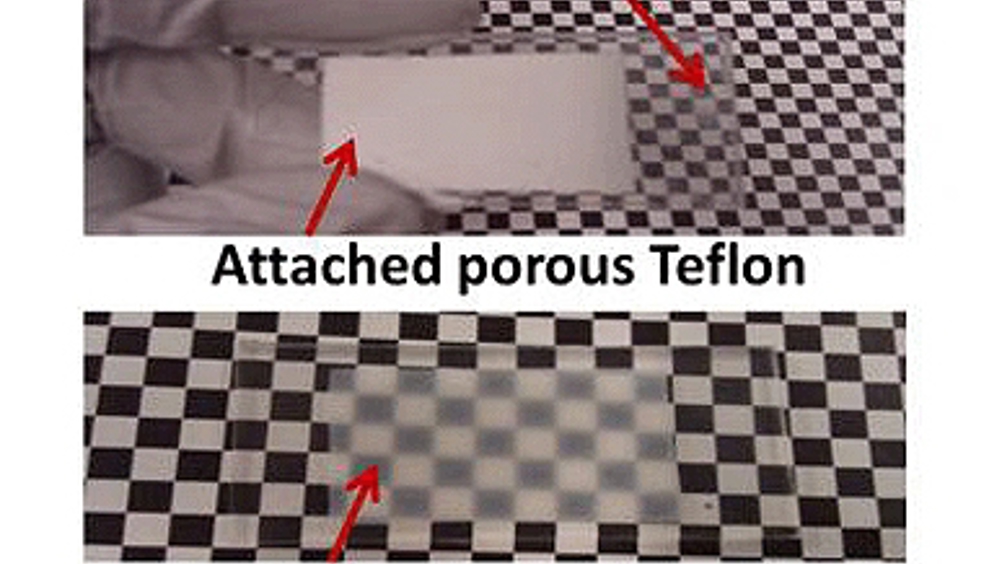

The bioinspired material is a continuous liquid film that coats, and is infused in, an elastic porous substrate. It is based on a core concept: any deformation of the substrate – such as stretching, poking, or swelling - changes the size of the pores, which causes the liquid surface to change its shape.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

UK Enters ‘Golden Age of Nuclear’

Apologies if this is a duplicate post - a glitch appears to have removed the first one: > While I welcome the announcement of this project, I note...