The tissue nanotransfection device, developed at the Indiana University School of Medicine and reported in Nature Protocols, brings the device a step closer to be used for medical treatment.

The non-invasive nanochip device can reprogram tissue function by applying an electric spark to deliver specific genes in a fraction of a second. In laboratory studies, the device converted skin tissue into blood vessels to repair an injured leg. The technology is currently being used to reprogram tissue for different kinds of therapies, such as repairing brain damage caused by stroke or preventing and reversing nerve damage caused by diabetes.

MORE FROM MEDICAL & HEALTHCARE

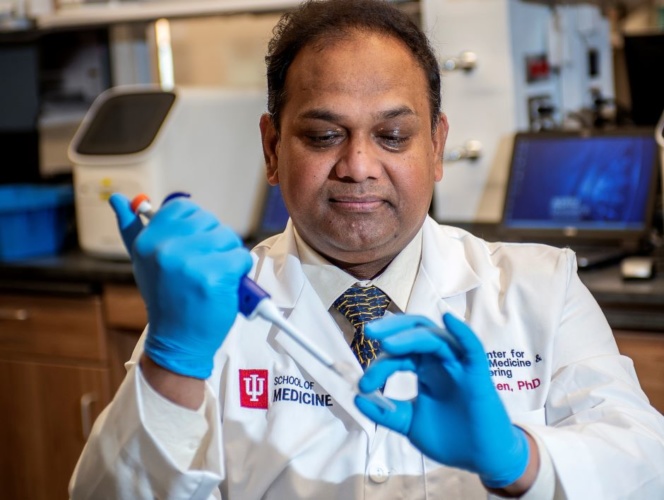

"This report on how to exactly produce these tissue nanotransfection chips will enable other researchers to participate in this new development in regenerative medicine," said lead author Chandan Sen, director of the Indiana Center for Regenerative Medicine and Engineering, associate vice president for research and Distinguished Professor at the IU School of Medicine.

Media kit: Access photos and video

"This small silicon chip enables nanotechnology that can change the function of living body parts," he said in a statement. "For example, if someone's blood vessels were damaged because of a traffic accident and they need blood supply, we can't rely on the pre-existing blood vessel anymore because that is crushed, but we can convert the skin tissue into blood vessels and rescue the limb at risk."

In the Nature Protocols report, researchers published engineering details about how the chip is manufactured.

Sen said this manufacturing information will lead to further development of the chip in hopes that it will someday be used clinically in many settings around the world.

"This is about the engineering and manufacturing of the chip," he said. "The chip's nanofabrication process typically takes five to six days and, with the help of this report, can be achieved by anyone skilled in the art."

Sen said he hopes to seek US FDA approval for the chip within a year.

Poll: Should the UK’s railways be renationalised?

Rail passenger numbers declined from 1.27 million in 1946 to 735,000 in 1994 a fall of 42% over 49 years. In 2019 the last pre-Covid year the number...