McLaren Racing aim for pole with Stratasys' 3D printing technologies

Ahead of Sunday’s Chinese Grand Prix, McLaren Racing has revealed how it is expanding the use of 3D printing as the team bids for glory on the track.

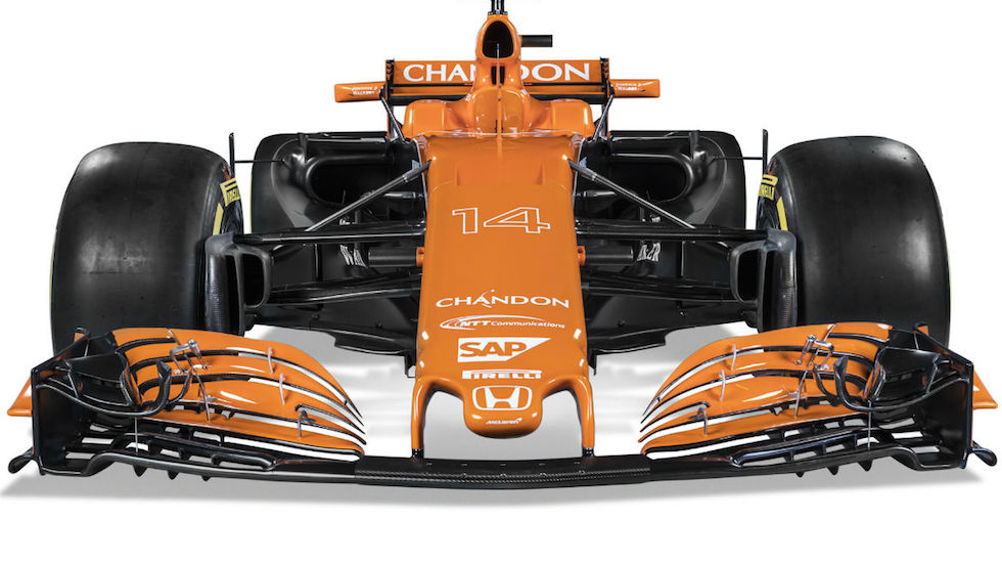

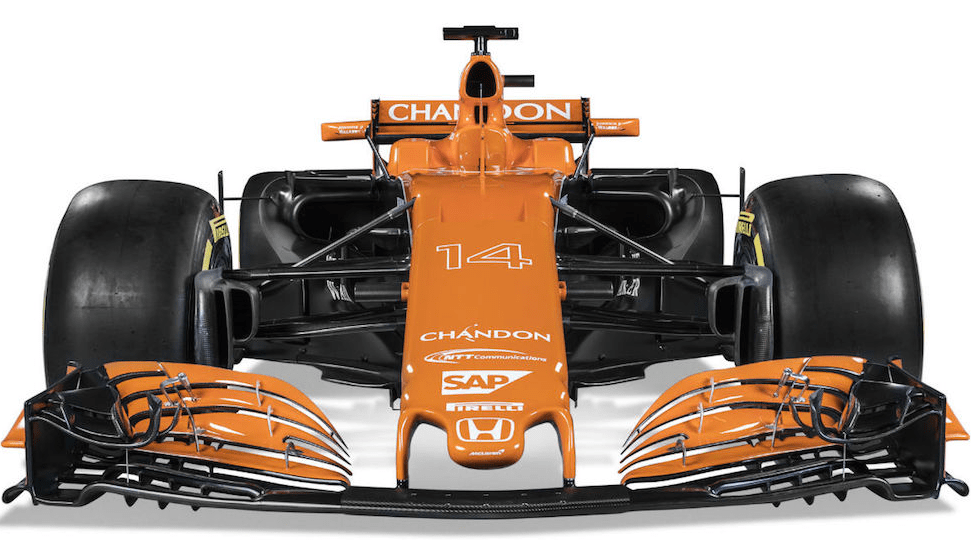

The Surrey-based team, which counts 12 drivers’ championships and eight constructors’ championships among its list of F1 honours, is using 3D printing technologies from Stratasys to accelerate design iterations and to reduce weight in McLaren Honda's MCL32 race car.

Some of the 3D printed parts designed to improve performance which have been applied to the 2017 race car include a hydraulic line bracket, a flexible radio harness location boot, carbon fibre composite brake cooling ducts, and rear wing flap.

The bracket for the MCL32 race car was produced in four hours compared to an estimated two weeks using traditional manufacturing processes. McLaren Honda 3D printed the structural bracket to attach the hydraulic line using Stratasys Fortus 450mc Production 3D Printer with carbon-fibre reinforced nylon material (FDM Nylon 12CF).

Similarly, a new 2-way communication and data system was recently added to the MCL32 race car but the cable distracted the driver. To overcome this, McLaren used the Stratasys J750 3D printer’s ability to print in flexible materials to produce a rubber-like boot to join the harness wires for the communication system. Three designs were iterated and 3D printed in one day. The final component was printed in two hours and was on March 26, 2017 at the Australian Grad Prix.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...