Metal jetting technology makes European debut

An additive manufacturing system that produces parts by jetting metal ink has made its European debut at the Formnext show in Germany.

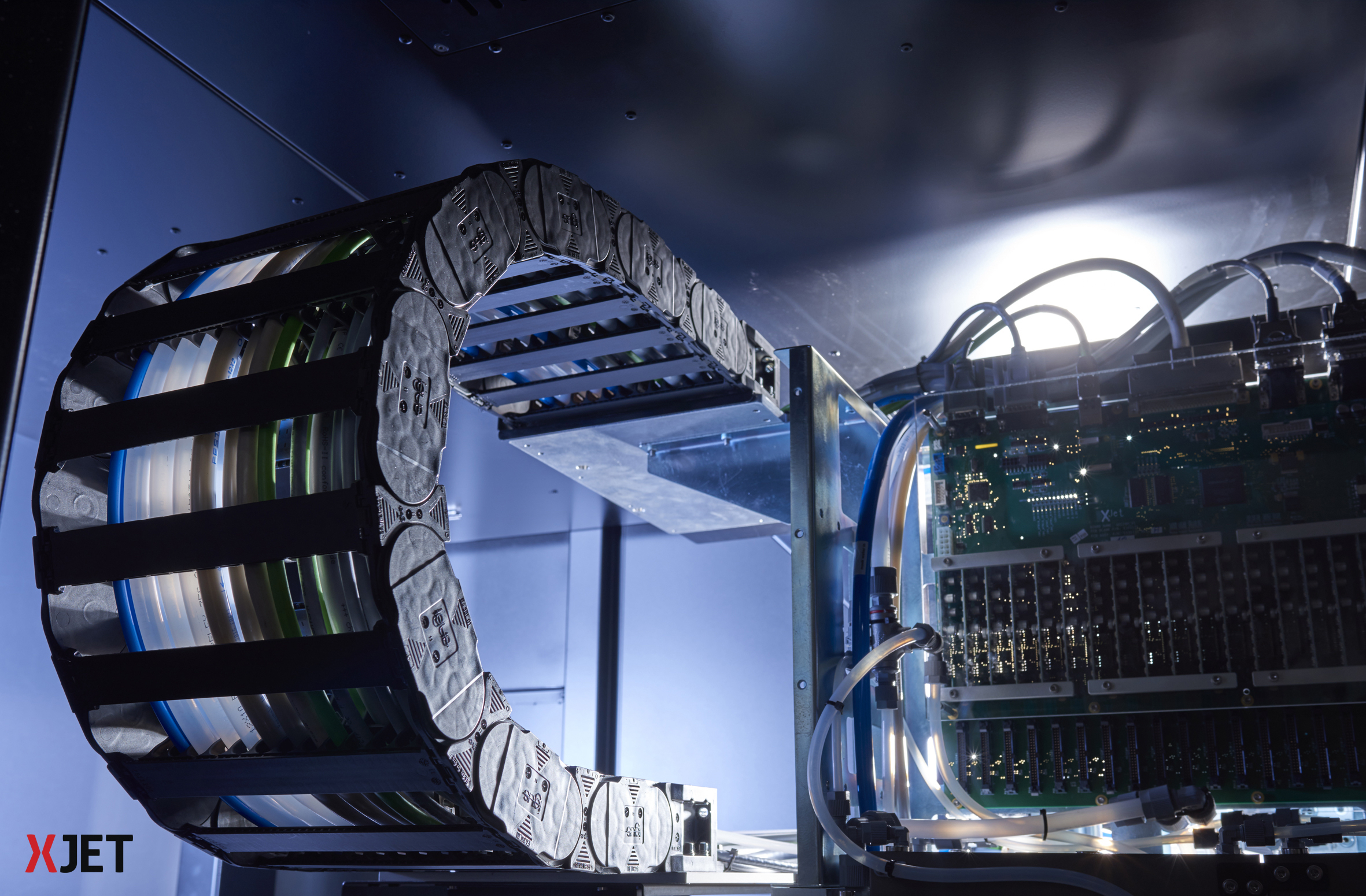

Developed by Israeli firm Xjet, the system is based on the company’s so-called NanoParticle Jetting technology, which uses ink jetting to produce complex metal parts from a suspension of nanoscale particles.

The firm claims that the system represents a fundamental breakthrough in additive manufacturing and produced higher quality, more detailed parts than is possible with existing metal additive techniques - most of which build parts from powdered metal.

The technology - which was demonstrated to the US market at the Rapid show earlier this year - uses solid metal nanoparticles suspended in liquid “ink” in sealed cartridges.

During the printing process, ultra-fine layers of droplets of this ink – which also contains support structure nanoparticles - are deposited onto the build-tray, where extremely high temperatures cause the liquid ‘jacket’ around the metal nanoparticles to evaporate. After this a sintering process is carried out to fuse the metal particles together.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

UK Enters ‘Golden Age of Nuclear’

Anybody know why it takes from 2025 to mid 2030's to build a factory-made SMR, by RR? Ten years... has there been no demonstrator either? Do RR...