Microbritt secures patent for method of machining brittle materials

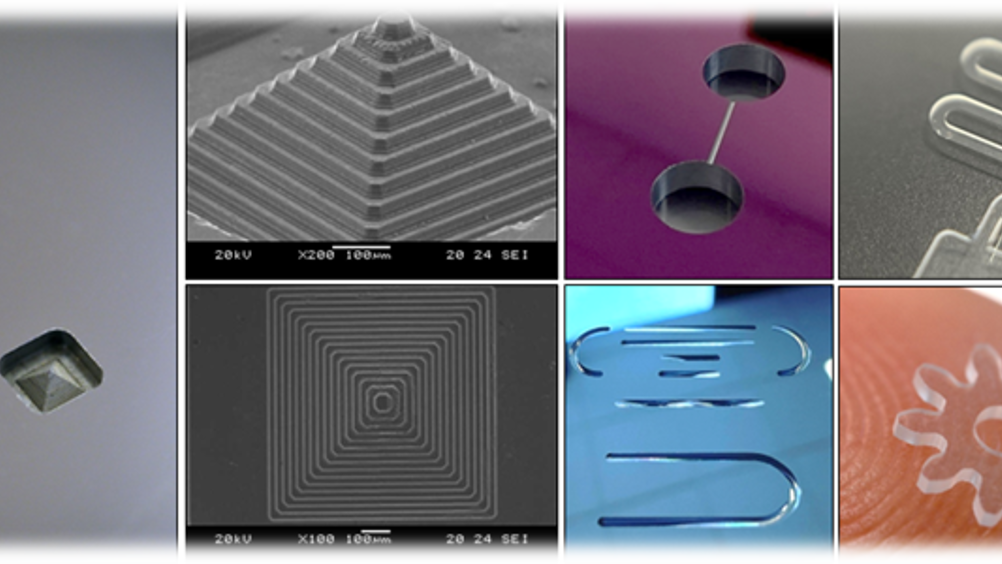

Newcastle-based Microbritt has secured a patent for its cutting method that enables the rapid manufacture of microscale products from brittle materials.

Microbritt's new patented micromilling method enables the high-precision fabrication of customer-defined products using materials such as silicon, glass, ceramics, and polymers. The patent has been granted in Europe and validated as a Unitary Patent (covering most EU countries) and a UK national patent.

Microbritt’s patented micro-milling method was first developed at Newcastle University and then commercialised to form a spinout company three years later.

The new method is said to improve the machining quality in brittle materials by using a technique that does not stress the material during the cutting process.

“This process is called a ductile machining process,” said Dr Carl Dale, CEO and co-founder of Microbritt. “Ductile machining reduces the energy put into the material and reduces the risk of damage. Brittle materials, like silicon used in the semiconductor industry, have previously been difficult to machine because of their fragility. Still, Microbritt’s new patented process makes this possible and brings established CNC machining technology into a new manufacturing domain.”

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

UK Enters ‘Golden Age of Nuclear’

The delay (nearly 8 years) in getting approval for the Rolls-Royce SMR is most worrying. Signifies a torpid and expensive system that is quite onerous...