The technique has been developed at North Carolina State University as part of an international collaboration that included Birmingham University and funding from EPSRC.

It is expected to give researchers a better understanding of materials including alloy 709, a stainless steel alloy with the potential for elevated temperature applications such as nuclear reactors.

“Alloy 709 is exceptionally strong and resistant to damage when exposed to high temperatures for long periods of time,” said Afsaneh Rabiei, corresponding author of a paper on the new findings and a professor of mechanical and aerospace engineering at NC State. “This makes it a promising material for use in next-generation nuclear power plants.

“However, alloy 709 is so new that its performance under high heat and load is yet to be fully understood. And the [US] Department of Energy needed to better understand its thermomechanical and structural characteristics in order to determine its viability for use in nuclear reactors.”

Working with Hitachi, Oxford Instruments and Kammrath & Weiss, Rabiei developed a new technique that allows her lab to perform scanning electron microscopy (SEM) in real time while applying extremely high heat and high loads to a material.

“This means we can see the crack growth, damage nucleation and microstructural changes in the material during thermomechanical testing, which are relevant to any host material – not only alloy 709,” Rabiei said. “It can help us understand where and why materials fail under a wide variety of conditions: from room temperature up to 1,000oC, and with stresses ranging from zero to two gigapascal.”

Rabiei’s team collaborated with Birmingham University to assess the mechanical and microstructural properties of alloy 709 when exposed to high heat and load.

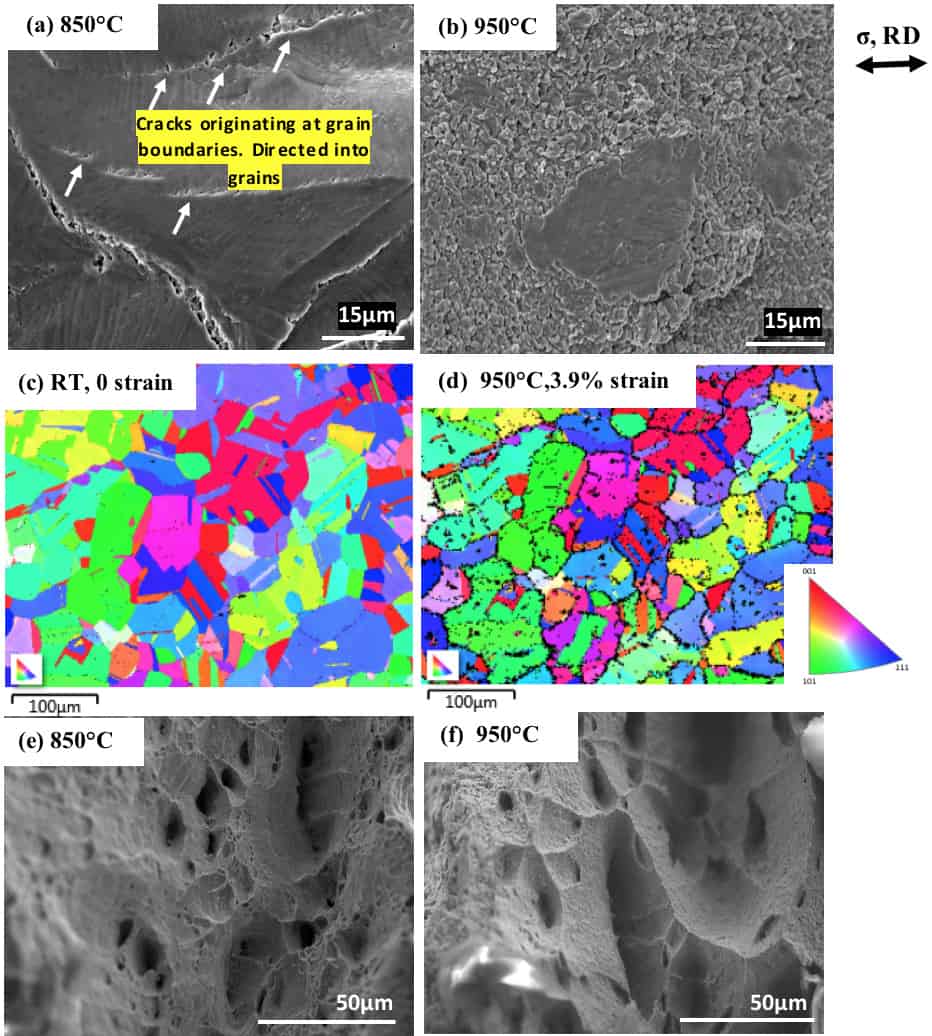

The researchers exposed 1mm samples of alloy 709 to temperatures as high as 950oC until the material failed.

“Alloy 709 outperformed 316 stainless steel, which is what’s currently used in nuclear reactors,” Rabiei said. “The study shows that alloy 709’s strength was higher than that of 316 stainless steel at all temperatures, meaning it could bear more stress before failing. For example, alloy 709 could handle as much stress at 950oC as 316 stainless steel could handle at 538oC.

“And our microscopy technique allowed us to monitor void nucleation and crack growth along with all changes in the microstructure of the material throughout the entire process,” Rabiei said.

“This is a promising finding, but we still have more work to do. Our next step is to assess how alloy 709 will perform at high temperatures when exposed to cyclical loading, or repeated stress.”

The paper, “A Study on Tensile Properties of Alloy 709 at Various Temperatures,” appears in Materials Science and Engineering: A.

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...