Microwave tech targets polypropylene waste

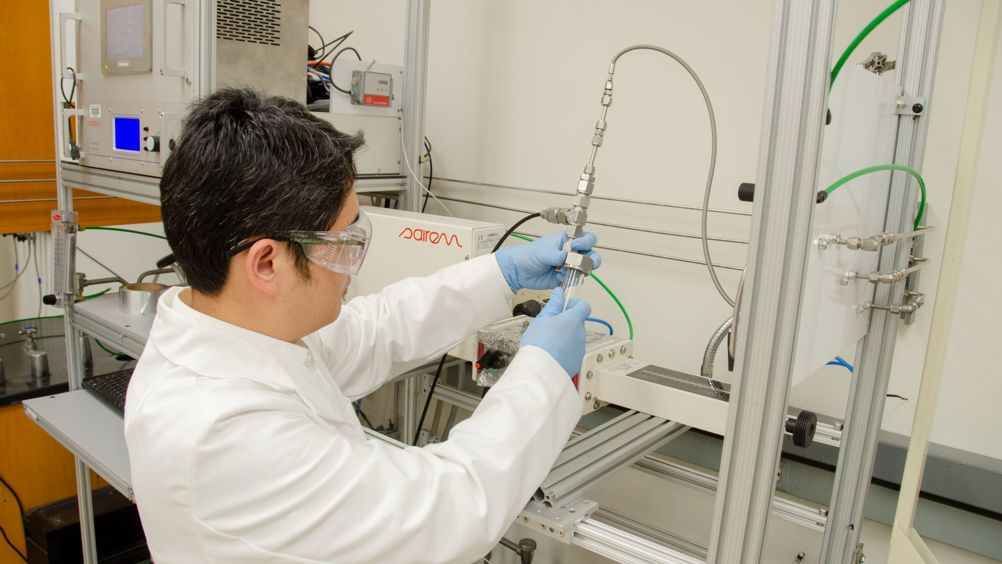

Engineers in the US have developed a new microwave-based technique for recycling polypropylene, an abundant plastic with a recovery rate today of just one per cent.

According to the West Virginia University (WVU) team behind the technology, the method relies on microwave radiation to heat an intermediary ‘catalyst’ material, which then transfers the heat to the polypropylene waste. Rather than breaking the material down into tiny pieces, the process converts polypropylene back into propylene, which can be reused in new plastics or other products.

“Currently polypropylene has a notably low recovery rate of only one per cent, meaning 99 per cent of polypropylene products become garbage,” said research lead Yuxin Wang, WVU chemical engineer and assistant professor at the university’s Benjamin M Statler College of Engineering and Mineral Resources.

“We want to change that by using microwave irradiation to recover propylene from polypropylene.”

Used in everything from food packaging to car parts, polypropylene is the second most abundant plastic after polyethene. And with recycling rates so low, the WVU team claims new processes are essential to reduce the material’s environmental impact.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...