More in

New 3D printing method gives boost to lithium-ion batteries

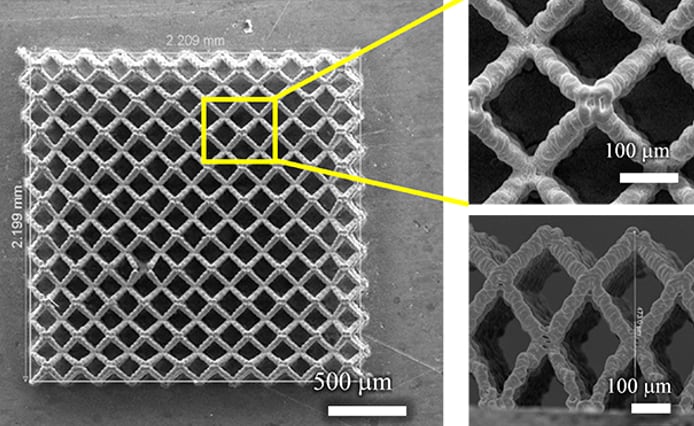

Engineers in the US have developed a 3D printing method that could lead to vastly improved capacity and charge-discharge rates for lithium-ion batteries.

Lithium-ion battery capacity can be vastly improved if their electrodes contain microscale pores and channels. To date, the internal geometry that produced the best porous electrodes through additive was interdigitated, which allows lithium to transport through the battery efficiently during charging and discharging, but is not optimal.

Now, Rahul Panat, an associate professor of mechanical engineering at Carnegie Mellon University, and a team of researchers from Carnegie Mellon in collaboration with Missouri University of Science and Technology have developed a new method of 3D printing battery electrodes that creates a 3D microlattice structure with controlled porosity. Their results are published in Additive Manufacturing.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...