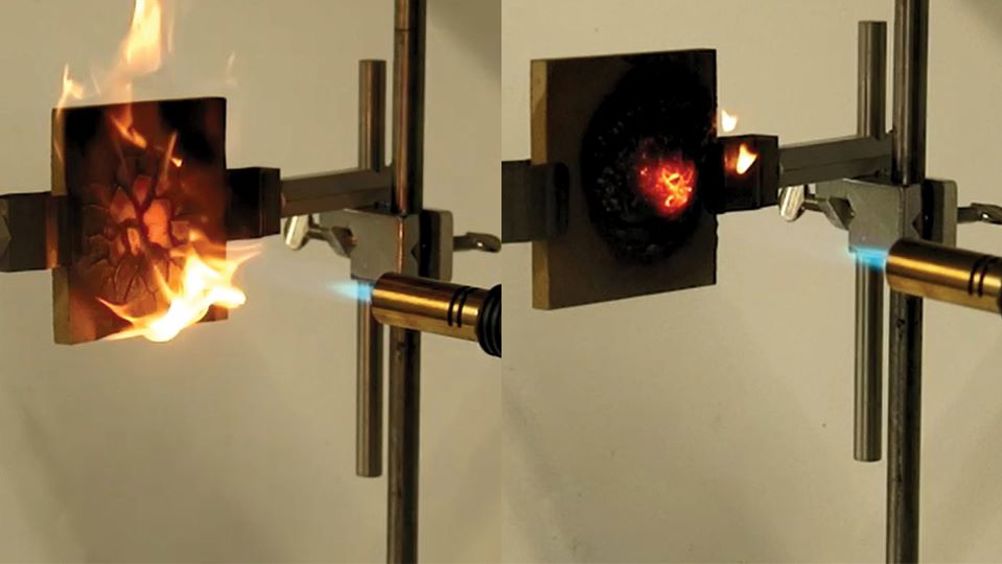

New epoxy resin is recyclable and flame retardant

An epoxy resin-based plastic that is recyclable, repairable and flame retardant has been developed at Empa, the Swiss federal laboratories for materials science and technology.

The new material, which is said to retain the favourable thermomechanical properties of epoxy resins, is detailed in Chemical Engineering Journal.

Epoxy resins are so-called thermosets, a type of polymer with closely crosslinked polymer chains that prevent melting or reshaping once the plastic has hardened.

Thermoplasts contain polymer chains that lie close together but are not chemically linked. When heated, these polymers can be melted and formed into new shapes. Because of the lack of crosslinks, their mechanical properties at elevated temperatures are generally not as good as those of thermosets.

The epoxy resin developed at Empa in collaboration with national and international partners is a thermoset that can be reshaped like a thermoplast. This was made possible with the addition of a functional molecule from the class of phosphonate esters into the new resin matrix.

"We originally synthesised this molecule as a flame retardant," said Empa scientist Wenyu Wu Klingler.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

BEAS funding available to help businesses cut energy costs

And not a moment too soon, if the following exchange broadcast last Friday 13th June, on the Radio 4 ´Rare Earth´ program (link below, ~ 17 minutes...