New method removes pollutants from industrial processes

For the first time, researchers have discovered a new method by which a catalyst can be used to selectively burn one molecule in a mixture of hydrocarbons.

This new method from the University of Minnesota Twin Cities could help in the removal of pollutants and improve efficiency for industrial processes ranging from the production of fuels and medications to fertilisers and plastics. The research is published in Science.

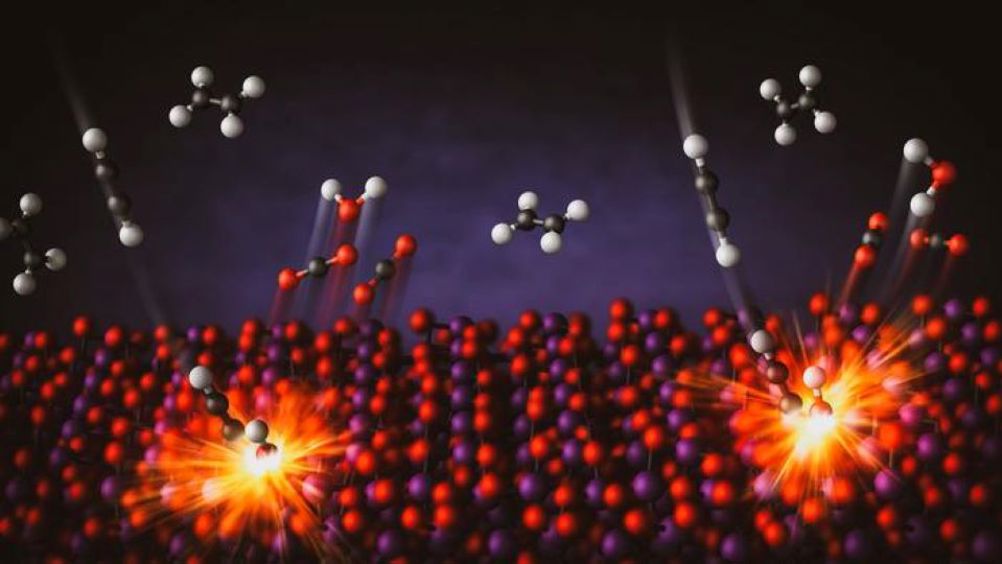

By using a bismuth oxide catalyst the researchers can selectively burn one molecule in a mixture of combustibles. The researchers showed that it is possible to effectively combust small amounts of acetylene in mixtures with ethylene. Removing acetylene is a crucial process to prevent poisoning of polymerisation catalysts, which is vital to produce polyethylene plastics.

“No one else has shown that you could combust one hydrocarbon present in low concentrations, in mixtures with others,” said Aditya Bhan, a Distinguished McKnight University Professor in the Department of Chemical Engineering and Materials Science and lead investigator on the paper.

Conventionally, combustion processes are used to burn hydrocarbon fuel mixtures at high temperatures to produce heat. The use of a catalyst allowed the researchers to tackle the challenge of burning one molecule but not the others. The bismuth oxide catalyst is claimed to be unique as it provides its own oxygen during combustion, rather than using oxygen from an outside source, in a process called chemical looping.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...