New moulding process opens the door to lightweight composites

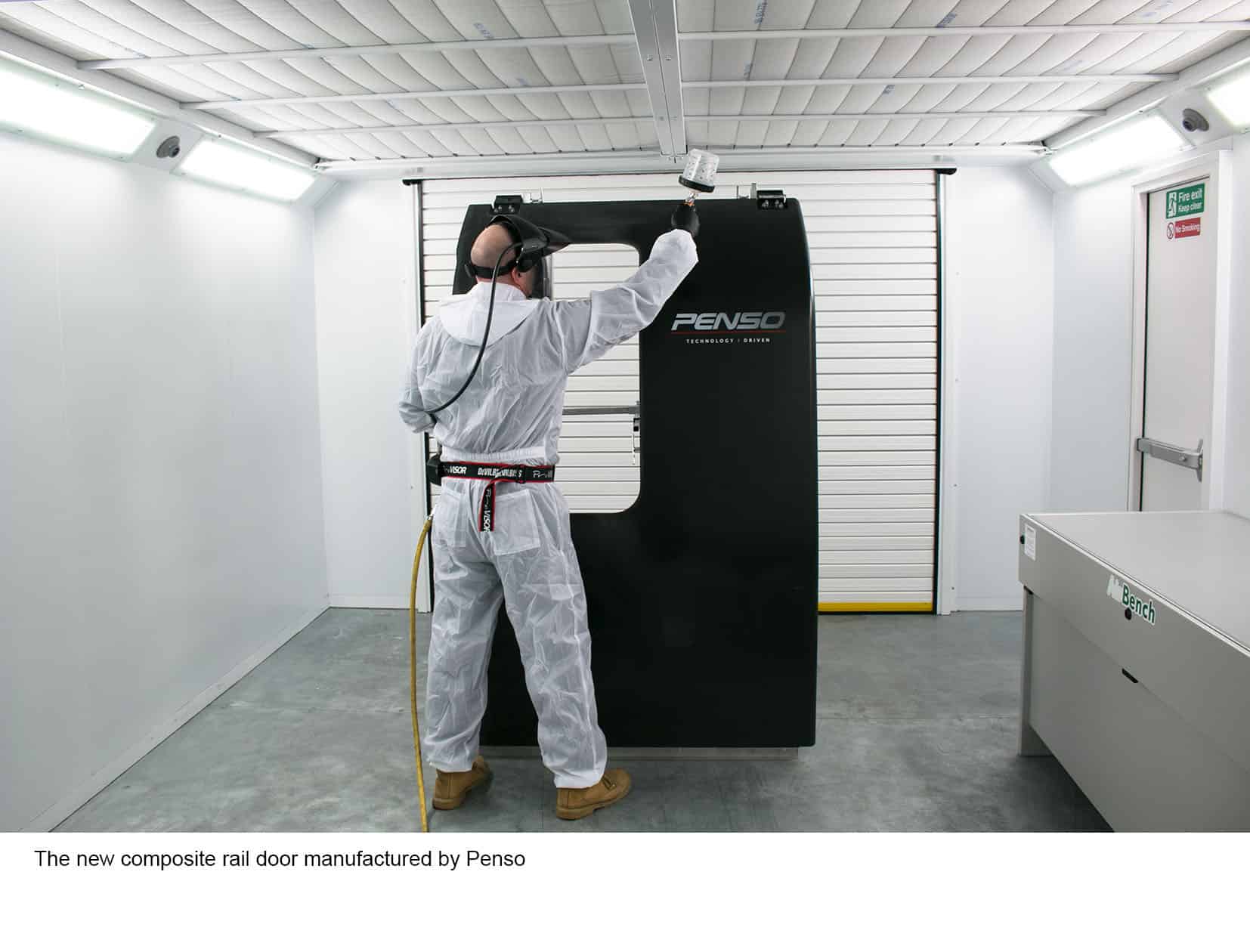

Penso Consulting has revealed an innovative composite door design that promises substantial weight savings for train carriages.

Showcased at the JEC World composites show this week in Paris, the new door uses a proprietary moulding technique that could have applications in other industries.

Penso uses a press-moulding process, with a phenolic pre-preg material wrapped around a solid core. The material itself is a relatively traditional composite that’s already widely used in aerospace, but the production process is understood to be unique.

“The key difference is that we cure the composite material with the core in-situ and the part is produced in one go,” said Paul Fannon, head of programmes at Penso. “We use a close-moulded two-shelled aluminium tool to cook the part. The whole process takes minutes, while you’re probably looking at five or six hours in an autoclave.”

This results in a closed composite structure, which eradicates the risk of moisture ingress. Penso cites this as an advantage over the current aluminium doors, which can suffer problems with delamination, but the greatest benefit comes in weight saving.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

BEAS funding available to help businesses cut energy costs

And not a moment too soon, if the following exchange broadcast last Friday 13th June, on the Radio 4 ´Rare Earth´ program (link below, ~ 17 minutes...