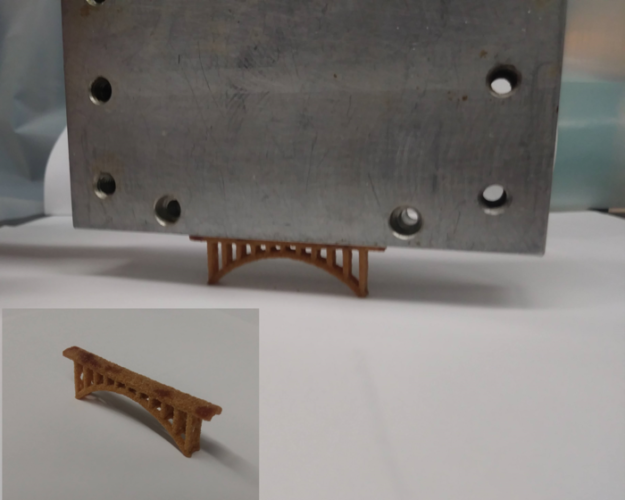

Described in Nature Communications, the polymer was used to create a 6.5cm long bridge able to support 300 times its own weight – the equivalent to the Brooklyn Bridge supporting 12 Empire State Buildings. The scientists behind the discovery say that sand parts embedded with the new polymer could be used as durable casts for tooling or carbon fibre manufacturing.

Silicon coating puts brakes on red light

Rice team developing 3D printed military ‘smart helmet’

To achieve these exceptional levels of strength, the sand was printed in combination with a tailored polyethyleneimine (PEI) binder that initially doubled the strength of parts versus existing binders. Post-printing, the parts were then treated with a superglue-type material called cyanoacrylate, which penetrates gaps and brings an additional eight-fold increase in strength. According to the researchers, the resulting polymer sand composite is stronger than any other known building material, including masonry.

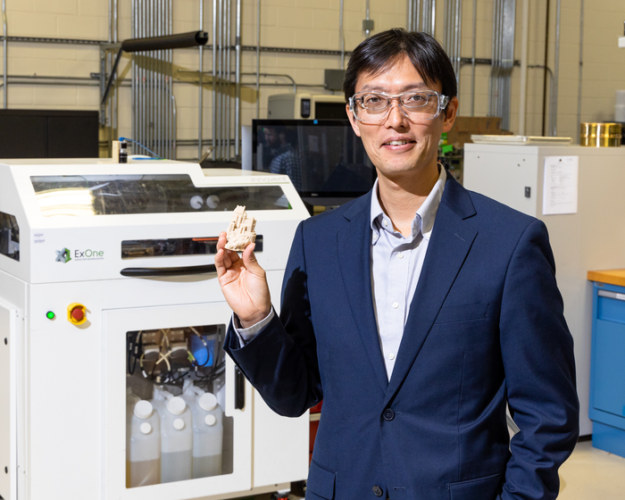

“Our key finding was in the unique molecular structure of our PEI binder that makes it reactive with cyanoacrylate to achieve exceptional strength,” said Tomonori Saito of the US Department of Energy’s Oak Ridge National Laboratory (ORNL), one of the project’s lead researchers.

“Few polymers are suited to serve as a binder for this application. We were looking for specific properties, such as solubility, that would give us the best result.”

For the manufacturing applications mentioned by the researchers, silica sand is an attractive casting medium because it does not change dimensions when heated and because it offers a unique advantage in washable tooling. In composite applications, using a water-soluble binder to form sand tools is significant because it enables a simple washout step with tap water to remove the sand, leaving a hollow composite form.

“To ensure accuracy in tooling parts, you need a material that does not change shape during the process, which is why silica sand has been promising. The challenge has been to overcome structural weakness in sand parts,” said study lead author Dustin Gilmer, from the University of Tennessee.

“Our high-strength polymer sand composite elevates the complexity of parts that can be made with binder jetting methods, enabling more intricate geometries, and widens applications for manufacturing, tooling, and construction.”

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...