New process shows promise for personalised prosthetics

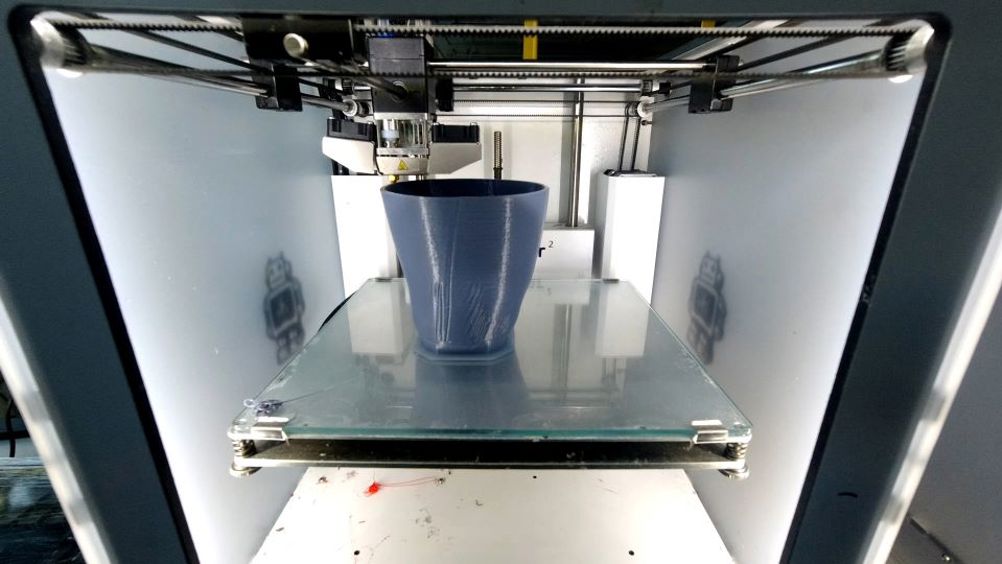

Lower limb prosthetic sockets could be printed in remote locations or users' homes with a fully digital design-to-manufacturing process developed at Loughborough University.

Traditionally, the creation of a lower limb socket has been a time-consuming process that takes around three-to-six weeks.

The method involves taking a cast of the limb that serves as a mould for crafting a socket, but the process requires hospital visits, relies on labour-intensive skills and expertise, and often involves a trial-and-error approach.

The resulting sockets can lead to skin and stability issues if they do not provide a perfect fit. Furthermore, the process has to be repeated frequently as sockets wear down quickly with use; they are replaced every three-to-six months for adults and more regularly for children.

Now, the new method developed by Dr Simin Li, a senior lecturer in Mechanics of Biomaterials in the School of Mechanical, Electrical and Manufacturing Engineering, utilises a variety of technologies and unique coding to create a socket through a fully digital process.

By capturing a 3D scan of the user's limb with a digital scanner and employing CAD software, a personalised design profile is generated, which can be imported into a 3D printer for manufacturing. According to Loughborough, the result is a fully customised socket that can be produced in as little as eight hours.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...