In tests on board a ship, the system pinpointed a motor with burnt-out wiring that could have led to an onboard fire.

The new sensor, whose readings can be monitored on an easy-to-use graphic display called a NILM (non-intrusive load monitoring) dashboard, is described in the March issue of IEEE Transactions on Industrial Informatics, in a paper by MIT professor of electrical engineering Steven Leeb, recent graduate Andre Aboulian MS '18, and seven others at MIT, the US Coast Guard, and the US Naval Academy. A second paper will appear in the April issue of Marine Technology, the publication of the Society of Naval Architects and Marine Engineers.

According to MIT, the system uses a sensor that is attached to the outside of an electrical wire at a single point, without requiring any cutting or splicing of wires. From that single point, it can sense the flow of current in the adjacent wire and detect the distinctive "signatures" of each motor, pump, or piece of equipment in the circuit by analysing tiny, unique fluctuations in the voltage and current whenever a device switches on or off. The system can also be used to monitor energy usage, to identify possible efficiency improvements and determine when and where devices are in use or sitting idle.

The technology is claimed to be especially well-suited for relatively small, contained electrical systems such as those serving a small ship, building, or factory with a limited number of devices to monitor. The system was tested last year on a Coast Guard cutter based in Boston.

Imminent failure

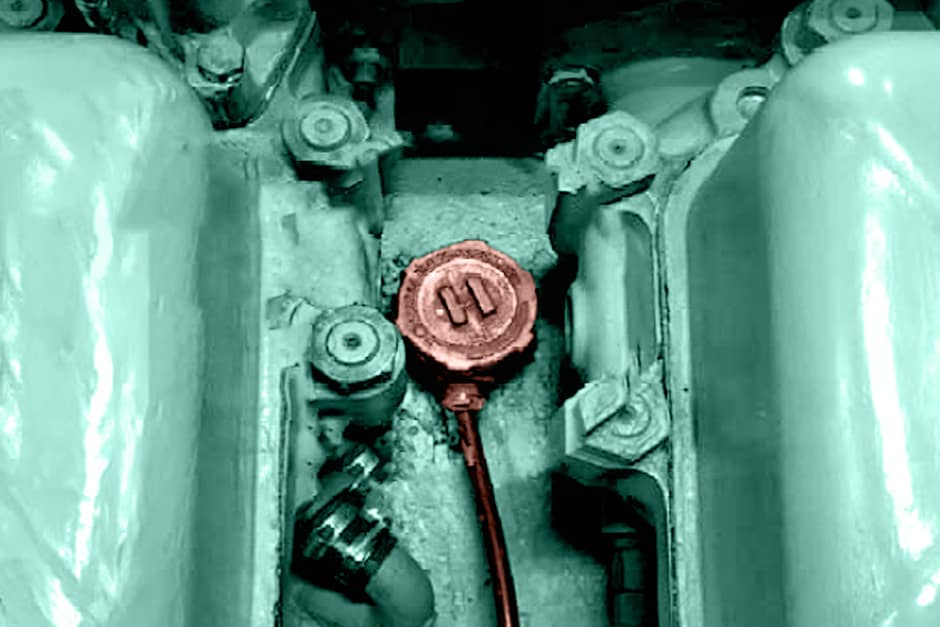

About 20 different motors and devices were being tracked by a single dashboard, connected to two different sensors, on the cutter USCGC Spencer. The sensors, which in this case had a hard-wired connection, showed that an anomalous amount of power was being drawn by a jacket water heater. The heaters are hidden under protective metal covers, but as soon as the cover was removed from the suspect device, smoke came pouring out and severe corrosion and broken insulation were revealed.

Lt. Col. Nicholas Galanti, engineer officer on the cutter, said: "The advance warning from NILM enabled Spencer to procure and replace these heaters during our in-port maintenance period, and deploy with a fully mission-capable jacket water system. Furthermore, NILM detected a serious shock hazard and may have prevented a class Charlie [electrical] fire in our engine room."

Detecting imminent failures before they become serious hazards is the dashboard's primary task, but Leeb pointed out that it can also perform other useful functions. By constantly monitoring which devices are being used at what times, it could enable energy audits or spot less-efficient motors that are drawing more current than their similar counterparts. It could also help ensure that proper maintenance and inspection procedures are being followed, by showing whether a device has been activated as scheduled for a given test.

Comment: Brute force can not solve autonomy challenge

Another few questions to ask, along with how effective an automated driving system is and whether the technology can be safely deployed on the...