Next-gen batteries could bring electric cars closer to market

Research chemists at BASF are developing next-generation lithium-ion batteries that will have significantly improved energy densities and lower material costs than existing products.

It is hoped the technology will increase the range of the current crop of hybrid vehicles and bring long-distance all-electric cars closer to mainstream production.

Company research director Dr Andreas Kreimeyer said: ‘Existing batteries are too expensive, their range is too limited and their weight is still much too high.

‘We must develop innovative concepts for more efficient electric cars if we are to convince potential users. Our activities must therefore be focused on guaranteeing a range of 400km for a battery weight of less than 200kg.’

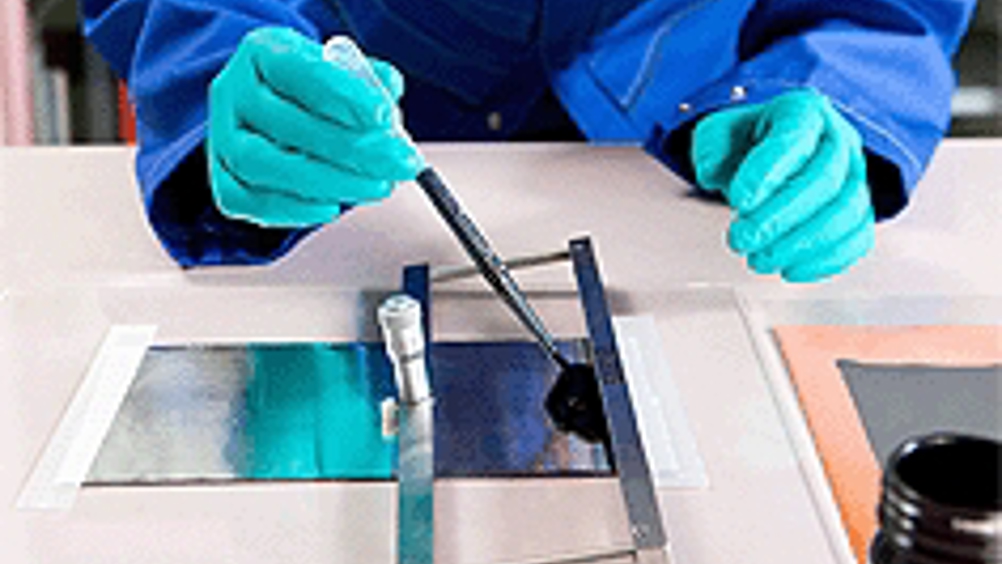

The first stage in this process will focus on producing new materials for the positive electrode, or cathode, of the battery.

The cathode is usually composed of a metal oxide, generally cobalt-based, while the negative anode is made of carbon, generally graphite. Cathode materials must be able to accept and release lithium ions repeatedly (for recharging) and quickly (for high current) — making them ripe for development.

‘To put it simply… we have to come up with a means of transport that ensures the fast transfer from the anode to cathode and back,’ said Prof Jürgen Janek, of Justus Liebig University Giessen, who heads the Scientific Network on Batteries, an academic research group supported by BASF.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

UK Enters ‘Golden Age of Nuclear’

The delay (nearly 8 years) in getting approval for the Rolls-Royce SMR is most worrying. Signifies a torpid and expensive system that is quite onerous...